Paper Machine 2500mm, 200 tpd, Fluting

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10505

- Name: Paper Machine 2500mm, 200 tpd, Fluting

Continuous Pulper (No.2)

• 14’ Black Clawson, rated at 240 BD tonnes / day @ 3.5%

• Junk trap, light rejects removed with overhead grab

• 2nd Hand unit , Installed in 1995

• Stainless steel construction

• 1.5 m wide feed conveyor

Ultrascreen

• Black Clawson Ultra V400, installed 2000

• 1st stage screen following 16’ pulper

• 400 m3 / hour @ 3.5% = 14.0 tonnes / hour

• 2mm holed extraction plate

• 110 KW drive motor running at 600 RPM

Turbo Separator (No.1)

• Voith ATS 021

• 2nd stage screen on 16’ line, treating rejects from Ultrascreen

• 70 m3 / hour @ 5.0% = 3.5 tonnes / hour (85 BD tonnes / day)

• 205 KW drive motor

Screw Compactor

• Beltec screw thickener supplied 2004

Elephant Filter

• Meri - Model 3-10 (Now Voith)

• 10-Disc unit, arranged in 5-banks of 2

• Maximum flow rate = 24.0 m3/hour, 3.2 tonnes / day

Trommel Screen

• Rotating drum design

• 10 BD tonnes / day @ 1.4%

Vibrating Screen

• 20 BD tonnes / day @ 5.0%

Thickstock Chest

• 200 m3 stainless steel chest, installed 2000

• 9.0 BD tonnes maximum stock holding at 4.5%

• Side mounted agitator

• 2 x Thickstock feed pumps, Scanpump BA 200/150 – 40, rated at 330 m3/hour

• Consistency control

PM1 STOCK APPROACH – BOTTOM WIRE

Refining

• Jylhavaara JCO2 conical refiner

• 5000 litres / min @ 6% = 18.0 tonnes / hour

Fan Pump

• Scanpump BA 350/350 – 45

• 17,200 litres / min @ 19.0m head

Primary Cleaners

• 48 x Voith HC5 – TB36 Cleaners

• 400 litres / min per unit = 19,200 litres / min total

Secondary Cleaners

• 19 x Voith HC5 Cleaners

• 400 litres / min per unit = 7,600 litres / min total Tertiary Cleaners

• 8 x Voith HC5 – TB1B Cleaners

• 400 litres / min per unit = 3,200 litres / min total

Quaternary Cleaners

• 4 x Voith Elutricone EBOB Cleaners

• 400 litres / min per unit = 1,600 litres / min total

• Continuous rejects

Final Stage Cleaners

• 2 x Palmac P200 RFD Cleaners

• 1,000 litres / min per unit = 2,000 litres / min total

• Intermittent rejects

Primary Screen

• Voith vertical screen Size 25

• 0.25 mm slotted basket

• 300 tonnes / day

Secondary Screen

• Voith vertical screen Size 12

• 0.20 mm slotted basket

• 20 tonnes / day @ 1.0%

• Common to top wire screening system

Rejects compactor

• Fan press, size 4

• Installed in 2004,

• Maximum flow rate = 1,500 litres / min @ 5.0%

• Maximum discharge solids content = 45.0%

PM1 STOCK APPROACH – TOP WIRE

Refining

• 2 x Metso JCO-1

• 100 tonnes / day output (combined max)

Fan Pump

• Scanpump BA 300 / 300 – 40

• 15,300 litres / min @ 0.6%, 38.0m head

Primary Cleaners

• 9 x Celleco TW 1500 combi cleaners

• 1,540 litres / min per unit @ 1.1% = 13,860 litres / min total Secondary Cleaners

• 2 x Celleco TW 1500 cleaners

• 1,400 litres / min per unit @ 0.9% = 2,800 litres / min total

Fibermizer

• 528 litres / min @ 0.6%

Stage 1R Cleaners

• 7 x LWR CLP 250 cleaners

• 250 litres / min per unit @ 0.6% = 1,750 litres / min total

Stage 2R Cleaners

• 1 x LWR CLP 250 cleaner

• 225 litres / min @ 0.5%

Primary Screen

• Voith vertical screen Size 20

• 0.20 mm slotted basket

• 15,000 litres / min @ 1.0% = 9.0 tonnes / hour No.1 MACHINE General Description

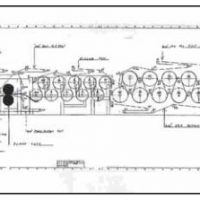

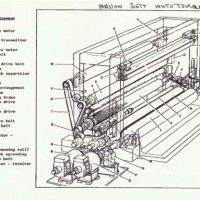

• Twin ply Fourdrinier machine with nominal deckle of 2,500mm

• Built in 1986, with a maximum design speed of 600 m/min

• SSD digital drive suite installed March 2005, L/hand drive.

• Current maximum operating speed – 600 m/min (at reel)

• Grammage range 90 GSM – 170 GSM. Production at 170 gsm = 10.5 t/hr.

• Testliner and Un-Dyed Chip

• ABB 1190 Advant DCS control system, with Smart Platform QCS dry-end scanner Flowbox (Bottom Wire)

• Simon Holder, rectifier roll flowbox

• 18 x manually controlled slice positioners

• Slice width – 2750mm

• Consistency range – 0.65% - 0.85%

• Flow rate – 11,000 litres / min (min) – 14,000 litres / min (max)

Wire Table (Bottom Wire)

• Simon Holder, bottom wire Fourdrinier

• Cantilever design

• Part ceramic, part plastic drainage elements

• Wire width – 2,900mm

• Wire length – 45.5m, couch to breast roll centres 27 mtrs.

• Single zone, suction couch roll with double doctor

• Variable position forward drive roll

• Steam profiling shower fitted over final tri-vac suction box

• Exit moisture circa 22%

Flowbox (Top Wire)

• Simon Holder, rectifier roll flowbox

• 18 x manually controlled slice positioners

• Slice width – 2,750mm

• Consistency range – 0.45% - 0.55%

• Flow rate – 5,000 litres / min (min) – 10,500 litres / min (max)

Wire Table (Top Wire)

• Simon Holder, top wire Fourdrinier

• Cantilever design

• Plastic drainage elements

• Wire width – 2,950mm

• Wire length – 20.6m

First Press

• Single felted, suction pick-up roll with 3 vacuum zones

• 2 x UHLE Box’s, with herring bone design plastic tops

• PU covered, with blind drillings and grooves

• Vacuum assisted save-all tray

• 450 PLi line load

• Synthetic covered plain pressing roll with double doctor

• Couch pit, with side entry agitator

• Open draw transfer to 2nd press, via William Kenyons tail transfer system, installed 2005

• Exit moisture circa 40%

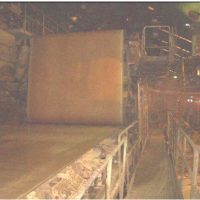

Second Press

• Large diameter jumbo press, 1.030 m diameter rolls

• Rubber covered with blind drill pattern

• Automated internal cooling system

• 1750 PLi line load

• Double felted

• 3 x UHLE Box’s, with herring bone design plastic tops

• Exit moisture circa 50%

Vacuum

• 2 x Nash 901, installed 2000

• 5 x Nash CL2001

• 1 x Nash CL1001

• 2 x 2-stage vacufoil fans for wire table low vacuum requirements

• Pre-separators and pumps

• Albany filter for recirculating seal water

• Seal water temperature control

Dryiers

• 3 x mechanical groupings arranged in 5 x steam sections:

o 1st Section – 3 x 1.2m diameter cylinders @ 1.8 barg

o 2nd Section – 7 x 1.2m diameter cylinders @ 1.8 barg o 3rd Section– 10 x 1.5m diameter cylinders @ 5.3 barg

o 4th Section– 5 x 1.5m diameter cylinders @ 10.0 barg

o 5th Section– 11 x 1.5m diameter cylinders @ 5.3 barg

• Potential to uprate 5.3 barg cyclinders to 7.5 barg, subject to re-cerification and insurance checks

• Johnson Systems International, thermo-compressor based steam system

• Steam groupings 1,2, 3 & 5 fitted with rotating siphons

• Steam group 4 fitted with stationary siphons

• Steam groupings 4 & 5 fitted with spoiler bars

• Drier group 1 configured with unirun drier fabric

• Drier groupings 2 & 3 configured with standard top & bottom drier fabrics

• Open gear drive train with part plastic, part metal gear wheels

• Partially enclosed hood with 2-fan PV System. Incorporates heat recovery from flash steam and condensate sources

• Automatic fabric tensioning (E & L)

• Automatic rope stretching (William Kenyons)

• SSD touch screen HMI control stations, installed 2005

Calender

• 2 x roll hard nip calendar

• Top roll diameter – 295mm

• Bottom roll diameter – 390mm

• Design nip load – 100PLi

Reel-Up

• Simon Holder drum reel

• Capable of producing single set parent reels, maximum diameter 1.6m

• Future upgrade potential to allow production of 4-set jumbo reels

• 5-tonne overhead crane

• UTM pulper with consistency control

• IBS automatic sheet turn-up system

• 30-reel spoils

• Belt driven, reel spool speed up system

• ABB Smartplatform scanner

• Maximum gross deckle – 2,580mm

General

• Anti-friction roller bearings throughout

• Automatic grease lubrication system

• Condition monitoring sensors installed on all major rolls, cylinders etc.

• HP showers on wet-end and press clothing, fitted with ruby nozzles

• Thermo compressors on dryers

• DCS control on stock prep

• Computer on machine ABB Advant 1190

Spares

• All major rolls

• Motors & gear-boxes for all drive positions

Finishing

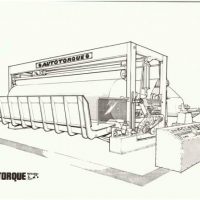

Rewinder

• Masson Scott Autotorque, twin-drum winder

• Maximum operating speed – 1,800 metres / min

• 2 x unwind stations for tambours,

• Unwind and rewind 1500mm diameter

• Shaftless rewind

• Brake driven tension control

• Rider roll

• Hydraulic reel lowering table

• PLC controlled, Eurotherm drive system

• Trim handling and conveying system

• Trim bale compactor, circa 3 tonnes / day

• Twin motor drive R/hand from unwinds

Backwater / Ancilliaries

Dissolved Air Floatation Unit

• Meri Deltafloat – Model 23, installed 1990

• Floatation surface area = 23m2

• Maximum flow rate = 185 m3/hour

• Operating in partial pressurisation mode

Drum thickener (No.2)

• Hedomora drum thickener

• Drum dimension – 0.75m diameter x 5.0m face length

• Thickens from 0.8% to 4.5%

• Spare drum

Heat & Power Generation

Package boilers

• 3 x Maxicon package boilers installed 1971

• Shell boiler design, each unit rated at 11.0 tonnes steam / hour @ 13.8 Bar

• Co-fuel capability – gas and LFO Gas turbine CHP

• Ruston (Now Siemens) TB5000 gas turbine, rated at 3.5 MWe

• Purchased as an unused, second hand unit in 1986 from Shell. Originally constructed in 1981

• Co-fuel capability – gas and LFO

• Gas compressor designed to raise incoming gas pressure from 3.0 to 11.0 Bar

• 33m Chimney

• Waste heat economiser installed in 1993

• Gas fired supplementary burner installed in 1993

Waste Heat Boiler

• Natural circulation water cooled boiler, rated at 26.0 tonnes steam / hour @ 13.8 barg, installed 1993

Steam turbine

• KKK steam turbine rated at 0.5 MWe @ 18tph steam flow

• Installed in 1987

• Steam pressure reduction from 13.8 barg to 2.8 barg

Gas engine CHP

• Caterpillar, 16-cylinder gas engine, installed 1991, Hrs 92,500. Sold

• Gas only

• Rated at 1.0 MWe and 1.5 tonnes / hour steam at 1.0 barg

• Hot water supply – 19m3/hour @ 40oC

Water Treatment

• Twin stream de-min plant (1986), rated at 12m3/hour

• Reverse osmosis plant (2001), rated at 12 m3/hour

General

• Steam accumulator (1993)

• Thermal de-areator (1993)

• Air compressors – various

• 5 x Oil-cooled transformers, stepping down from 11KV to 415V. Ratings:

o 2 x 1,000 kVA

o 1 x 1,500 kVA

o 2 x 2,000 kVA

o 1 x 2,500 kVA

• HT & LT distribution equipment for PM1

• Power factor correction equipment