2-Wire Fourdrinier-Type Paper Machine for the production of Corrugated Base (Kraft) Paper, Width 2550mm

-

Print this page

- Product ID: VAK10627

- Name: 2-Wire Fourdrinier-Type Paper Machine for the production of Corrugated Base (Kraft) Paper, Width 2550mm

- Year: 1956

- Capacity: 150 t/d

- Type: Fourdrinier

FOR THE MOMENT ON HOLD

2-WIRE FOURDRINIER-TYPE PAPER MACHINE

| Make | VOITH |

| Year of Make | 1956 |

| Years of major rebuilds | 1989New dryer part 1996New bottom wire headbox 1998Rebuild of slitter rewinder 2000Rebuild of wire part 2002Rebuild of slitter rewinder 2004New QCS 2007Rebuild of Pope Reel |

| Sheet width at Pope reel | 2550mm |

| Paper Grade | Testliner (brown) |

| Basis weight range | 125–270g/m2 |

| Operating speed max. | 320m/min |

| Capacity | 150t/24h |

| Electric | 500V, 50Hz |

| Drive side | right, seen in paper run direction |

| Raw material | Waste Paper, OCC |

CONSISTING OF:

Stock Preparation and Approach Flow System

Stock Preparation joint line for top and bottom ply

(Capacity 220 tpd)

1 Pulper, type Hydrapulper D, 20 m3, Rotor 50”,

make BLACK CLAWSON including conveyor belt,

drive and drive control

1 Detrashing System, type Hydrapurge, make

KADANT-BLACK CLAWSON

1 Reject-Screening Drum, type Selectpurge, make

KADANT-BLACK CLAWSON

1 High Consistency Cleaner, type Liquid Cyclone,

make THERMO-BLACk CLAWSON

1 Pressure Screen as primary screen, Type UVF400,

make KADANT-BLACK-CLAWSON, basket with holes

1.8mm dia, incl. drive

1 Pressure Screen as secondary screen, Type Diabolo,

make KADANT-LAMORT incl. drive

1 Hydrascreen as tertiary screen, make KADANT-LAMORT

1 Fractionising Pressure Screen, type UVF400, make

KADANT-BLACK-CLAWSON with slotted basket 0.18 mm,

incl. drive. Long fibres used for toplayer and short

fibres for bottom layer. Including all tanks, chests,

pipes, pumps, valves, instruments, drives and controls

Approach Flow for bottom layer

1 Fan-Pump, type ABS BA300-40, make SCANPUMP,

throughput 1000 m3/h incl. drive

1 Low-Density Cleaner “Liquid Cyclone 20”,

make KADANT-BLACK-CLAWSON

1 Pressure Screen 1st stage, type Selectifier PS30,

make KADANT-BLACK- CLAWSON, basket with

slots 0.25 mm dia, incl. drive

1 Pressure Screen 2nd stage, type SP600,

make KADANT-LAMORT, basket with Slots 0.30 mm,

incl. drive

1 Pressure Screen 3rd stage, type Diabolo DTZ,

make KADANT-LAMORT, basket with slots 0.30 mm,

incl. drive Including all tanks, chests, pipes,

pumps, valves, instruments, drives and controls

Approach Flow for top layer

1 Fan-Pump, type ABS BA300-40, make SCANPUMP,

throughput 800 m3/h incl. drive

1 Low-Density Cleaner “Liquid Cyclone 20”,

make KADANT-BLACK-CLAWSON

1 Pressure Screen 1st stage, type Miami 24”,

make KADANT-BLACK CLAWSON basket with

holes 1.6 mm dia, incl. drive

1 Vibration screen 2nd stage, incl. drive

1 Refiner, make PILAO including all tanks, chests, pipes,

pumps, valves, instruments, drives and controls

For Broke System

Complete including wet and dry broke pulpers, deflakers and thickeners, including all tanks, chests, pipes, pumps, valves, instruments, drives and controls

Fibre Recovery System

1 Flotation System, type Supercell 18’, make KROFTA

Including all tanks, chests, pipes, pumps, valves,

instruments, drives and controls

PAPER MACHINE

Bottom Wire complete, with air cushion headbox, make ALLIBE, throughput 900 – 1560 m3/h with manual basis weight cross-profile, wire part frames cantilevered for time-saving bottom wire change, 1 forming board, 10 Hydro-Foils, 4 Vacu- Foils, all with PE-covers, 8 Suction boxes with ceramic covers, breast roll rubber covered, suction couch roll with bronze steel shell 750 mm dia used as drive roll, including pneumatic wire guide and electric wire stretcher, including high and low-pressure cleaning showers

Top Wire complete, with air cushion headbox, type ISOFLOT, make NEYRPIC, throughput max. 1000 m3/h with manual basis weight cross-profile control, wire part frames cantilevered for time saving top wire change, 1 forming board, 5 Hydro-foils, 1 Vacu-foil, 1 Suction-box, all with PE covers, 8 suction boxes with ceramic covers, breast roll rubber covered, forming roll, including pneumatic wire guide and electric wire stretcher, including high and low-pressure cleaning showers.

Press Part

1st Press straight-thru with bottom suction press roll 750 mm dia, top press roll 550 mm dia, make VOITH, linear nip pressure 40 kN/m, with bottom press felt run, including felt guide, felt stretcher and felt conditioning equipment

1 Steam-Blow Box, make DEVRON

2nd Press straight-thru with bottom press roll 710 mm dia, top press roll 710 mm dia, linear nip pressure 140 kN/m, with bottom press felt run including felt guide, felt stretcher and felt condition equipment

3rd press straight-thru with bottom press roll 710 mm dia, top press roll 710 mm dia, 140 kN/m linear nip pressure, with top and bottom felt run including felt guide, felt stretcher and felt conditioning equipment

Pre-Dryer Part

1 Pre-Dryer Part with 18 drying cylinders 1500 mm diameter, first 3 dryers designed for 5 bars, 15 dryers designed for 8 bars steam pressure, including condensate removal equipment, including top and bottom fabric run and including central oil lubrication system for all drying cylinder bearings, including rope-feeding system

1 semi-closed hood and ventilation system, including heat recovery system

1 steam and condensate system type Cascade, make THERMOPAP

1 M.G. Cylinder 5000 mm make VOITH, designed for 3.5 bars steam pressure, including touch-press roll, including felt run and steam fired hood, make THERMOPAP, including rope feeding system and central oil lubrication system for cylinder bearings

Size Press

1 horizontal size press, with size press rolls 520 mm dia, including drive

After-Dryer Part

1 After-Dryer Part with 12 drying cylinders, 1500 mm diameter, 1st cylinder designed for 5 bars steam pressure, all others for 8 bars steam pressure, including condensate removal system and including central oil lubrication system for all drying cylinder bearings, including rope-feeding system

1 hood and ventilation system with semi-closed hood and including pocket- ventilation system make BRUNSCHWEILER, including heat recovery system

1 steam and condensate system with thermocompressor, make BRUNSCHWEILER,

1 steam profiler, make DEVRON 2.7 Machine Soft-Calander

Not installed but all part available in dismantled condition

QCS

1 Online-Quality Control Scanner for the online measurement of basis weight and moisture cross profile, type Paper IQ, make METSO

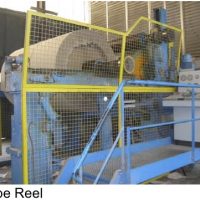

Pope Reel

Hydraulic Pope reel, type Mandrins, make ALLIBE 2.10

Machine Drive

Sectional drive with individual motors, make ABB for wire part, after-dryer-part and Pope reel. Line shaft drive for press part, pre-dryer part including M.G. Dryer. Including drive and drive control.

Vacuum System

| 1 Vacuum Pump, type AL30/31, make SAFEM, drive 110kW |

| 1 Vacuum Pump, type AL30/32, make SAFEM, drive 132kW |

| 1 Vacuum Pump, type VG49, make ALLIMAND, drive 55kW |

| 2 Vacuum Pumps, make VOITH, drive 60kW |

| 1 Vacuum Pump, type AL20/21, make SAFEM, drive 90kW |

| 1 Vacuum Pump, type SNH40, make HIBBON, drive 37kW |

| 1 Vacuum Pump, make VOITH, drive 27kW |

2 Vacuum Pumps, type AL40/42, make SAFEM, drive 160 kW for all dewatering elements, suction rolls and suction pipes of this machine, including all separators, tanks, pipes, drives, drive controls and instruments.

Finishing House Equipment

1 Slitter Rewinder Make GOROSTIDI, year of make 2000, with 2 carrier rolls, 2 slitting knifes. Max. speed 1500 m/min. Including drive and drive control

Auxiliary Equipment

Machine Hall Cranes, one with 10t the other with 5 t lifting capacity

Steam and Power Supply

Steam boiler, make SOCOMAS, with gas-burner PILLARD, year of make 1996 including boiler water preparation

Spare Parts & Technical Documentation

| Spare Rolls f. paper machine | One spare roll available for each position |

| Spare Motors | Included as far as available |

| Techinical Documentation | Included as far as available |

| Condition | Machine was fully operational when shut in |