BOARD MACHINE 3500mm, 77,000 t/year, VOITH-DÖRRIES

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10663

- Name: BOARD MACHINE 3500mm, 77,000 t/year, VOITH-DÖRRIES

|

Type |

combined Fourdrinier-Former |

|

Make |

VOITH-DÖRRIES |

|

Year of make |

1961 Many rebuilds until 2007 |

|

Capacity of board machine |

77.000t/year |

|

Capacity of stock preparation |

150.000t/year |

|

Sheet width at Pope Reel |

app. 3600mm |

|

Sheet width trimmed |

3500mm |

|

Board Grade |

* Coated Board grades * Grey Board medium smooth * Grey Board one-side smooth * Various special grades |

|

Basis Weight Range |

300 – 600g/m2 |

|

Thickness Range |

0.4 – 1.01mm |

|

Raw Material |

* Mixed waste for Filler

* White Cuttings and Virgin Pulp for Top

* Light printed waste for Underlayer and Back |

|

Drive side |

right, seen in paper run direction |

Line 3 for mixed waste and litho waste

1 Hydra-Pulper, make BLACK CLAWSON, type 14”

1 Ragger-Winder

1 Stock Washer, make GW FASERTECHNIK, type MWS11

1 Contaminex, make VOITH, size 11

1 stainless steel chest with agitator, make LAMORT, type 612/100

1 High-consistency Cleaner, make LAMORT, type L.A.250/3200 (EPE)

1 Double-Separator, make LAMORT, type ADS7 Finer, hole 2.5mm,

slot 0.25mm

1 Final Stage Screen, make LAMORT, type Diabolo 35, hole 2.5mm

1 Horizontal Pressure Screen, make LAMORT, type CH7, slot 0.25mm

1 Final Stage Screen, make LAMORT, type Diabolo 35, slot 0.25mm

1 Belt-Filter Thickener, make VOITH, type SB2

1 Hot-Dispersion Plant, make VOITH, Size 200

Line 5 for loose mixed waste and OCC

1 Hydra-Pulper, make BLACK CLAWSON, type 14”

1 Ragger-Winder

1 Stock Washer, make GW FASERTECHNIK, type MWS11

1 Contaminex, make VOITH, size 11

1 stainless steel chest with agitator, make LAMORT, type 612/100

1 High-Consistency Cleaner, make LAMORT, type L.A.250/3200 (EPE)

1 Double Separator, make LAMORT, type ADS7 Finer, hole 2.5mm,

slot 0.25mm

1 Final Stage Screen, make LAMORT, type Diabolo 35, hole 2.5mm

1 Horizontal Pressure Screen, make LAMORT, type CH7, slot 0.25mm

1 Final Stage Screen, make LAMORT, type Diabolo 35, slot 0.25mm

Line 6 for white cuttings and bright carton waste

1 Hydra-Pulper, make BLACK CLAWSON, type 14”

1 Fibre Sorter, make ESCHER WYSS, type FS2B

1 High Consistency Cleaner, make ESCHER WYSS, type D1PS

1 Fibre Sorter, make ESCHER WYSS, type FS1B

1 Reject Sorter, make ESCHER WYSS, type RS2B

Common Stock Prep Equipment

1 Sorting Drum, make VOITH, 10mm holes

1 Reject Press, make BAB-BELTEC, type Belpress BP601

1 Sand Classifier, make STRELEY, type 500

1 Sand Classifier, make STRELEY, type 200

1 Conveyor Belt, make B+G FÖRDERTECHNIK

Entire stock preparation complete with all pipes, pumps, valves, tanks, chests, agitators, measuring and control elements, all drives and drive controls.

BOARD MACHINE

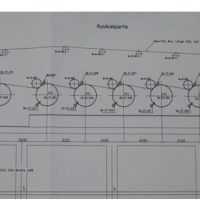

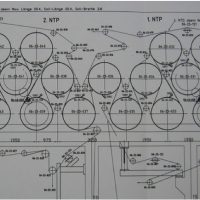

Former-Part

2 Suction Formers, make VOITH DÖRRIES including headbox and couching roll

6 Short Formers, make VOITH DÖRRIES, including headbox and couching roll

1 complete Top Carrier Felt Run including 1 Pulling Press, 1 Felt Washing station with high and low pressure showers as well as suction pipes, Felt Stretcher and Felt Guide

1 complete Bottom Carrier Felt Run including Pre-Suction Press with one suction press roll and one plain press roll, Felt Washing Station with high and low pressure showers as well as suction pipes, Felt Stretcher and Felt Guide

1 Couch Broke Pulper

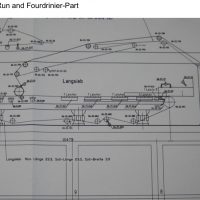

Transfer Felt-Run and Fourdrinier-Part

1 complete Transfer Felt from Former-Part to Wire Part w. Felt Stretcher and Felt Guide

1 Headbox, open-type

1 Wire Part incl. 1 rubber covered Breast Roll, 1 Forming Board, 4 Foil Boxes

1 Forming Roll, 1 Steam Blow Box, 4 Suction Boxes, 1 Suction Couch Roll including drive, 1 rubber covered Couching Press Roll incl. drive, 6 rubber covered Wire Rolls, all wire rolls outside of wire with cleaning doctor, 4 High and Low Pressure Cleaning Showers, 1 Wire Stretcher, 1 Wire Guide, 1 Roll-out system for wire change, all frames, stands, beams and brackets

1 Top-Felt-run for Couching Press Roll incl. cleaning shower, felt stretcher, felt guide

1 Couch Broke Pulper

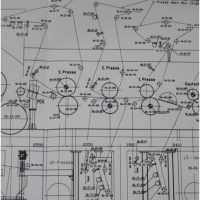

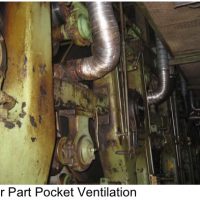

Press Part

1ststraight-thru Suction Press with top and bottom felt includes:

* 1 Bottom Suction Press Roll with rubber cover and drive

* 1 Top Press Roll with rubber cover blind drilled

* 1 Bottom Felt Run with steam blow box, high and low pressure

cleaning showers, 2suction pipes, felt stretcher and

felt guide

* 1 Top Felt Run with high and low pressure cleaning showers,

2 suction pipes, feltstretcher and felt guide

2ndstraight-thru Press with top and bottom felt includes:

* 1 Bottom Press Roll with rubber cover blind drilled and drive

* 1Top Press Roll with rubber cover blind drilled

* 1 Bottom Felt Run with high and low pressure cleaning showers,

2 suction pipes, feltstretcher and felt guide

* 1 Top Felt Run with high and low pressure cleaning showers,

2 suction pipes, feltstretcher and felt guide

3rdstraight-thru Press with bottom felt includes:

* 1 Bottom Press Roll with plain rubber cover

* 1 Top Press Roll with rubber cover blind drilled and drive

* 1 Top Felt Run with high and low pressure cleaning showers,

2 suction pipes, feltstretcher and felt guide

* 1 Press-Broke Pulper

* 1 Quality Control Scanner for measuring of cross profile of

moisture

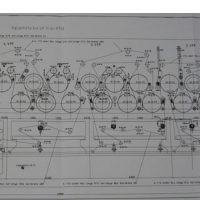

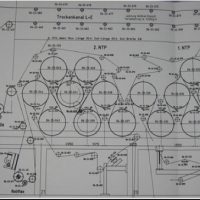

Pre-dyer Part

5 dryer groups with totally 27 drying cylinders, 2 MG-cylinders, 4 of them with totally enclosed hood, including process controlled air ventilation, vapour extraction and heat recovery, including all fans, ducts and controls. All dryers and fabric rolls with central oil lubrication

1stDryer Group with 6 drying cylinders 1500mm diameter, steam heated, including bottom fabric run with fabric stretcher and fabric guide, including pocket ventilation

2ndDryer Group with 6 drying cylinders 1500mm diameter, steam heated, including top and bottom fabric run with fabric stretcher and fabric guide, including pocket ventilation

3rdDryer Group with 6 drying cylinders 1500mm diameter, steam heated, including top and bottom fabric run with fabric stretcher and fabric guide, including pocket ventilation

4thDryer Group with 9 drying cylinders 1500mm diameter, steam heated, including top and bottom fabric run with fabric stretcher and fabric guide, including pocket ventilation

5thDryer Group with 1 Pre-M.G. Cylinder 4500mm diameter, 1 M.G. Cylinder 5000mm diameter with German Press, both steam heated, including cleaning doctors and dryer fabric runs with fabric stretchers and fabric guides,

Wet-Calander Part

1 Wet-Machine Calander with 1 Swimming Roll and 1 heated calander-roll made of chilled cast iron

Size Press

1 Horizontal Size Press with 2 size press rolls and 2 gas-fired IR-dryers

1 Dry Broke Pulper below size press

After-Dryer Part

2 dryer groups with totally 17 drying cylinders, both with totally enclosed hood, including process controlled air ventilation, vapour extraction and heat recovery, including all fans, ducts and controls, All Dryers and fabric rolls with central oil lubrication

1stAfter-Dryer Group, 3-row with 9 drying cylinders 1500mm diameter, steam heated, including top and bottom fabric run with fabric stretcher and fabric guide

2ndAfter-Dryer Group, 3-row with 8 drying cylinders 1500mm diameter, steam heated, including top and bottom fabric run with fabric stretcher and fabric guide,

Coating Part

1 Coating Station with Rollflex Applicator and 1 gas-fired IR-Dryer

1 Coating Station with Blade Applicator and 1 gas-fired IR-Dryer

1 Coating Station with Airbrush Applicator and 1 gas-fired IR-Dryer

1 Air-Channel-Dryer, steam heated

1 Coating Station with Roll-Rod Applicator and 1 gas-fired IR-Dryer

1 Air-Channel Dryer, steam heated

1 Cooling Cylinder 1500mm diameter, chrome plated

End Group

3-Roll Machine Calander

1 Machine Calander with 1 swimming roll, one heated and one plain calander roll

Quality Control Scanner

1 Quality Control Scanner for online measuring of important quality parameters like moisture profile, basis weight profile, thickness etc

1 Dry Broke Pulper including belt conveyor

Pope Reel Part

1 Hydraulic Pope Reel for reel diameters up to 2000mm

Machine Accessories

Machine Drive

Dryer Part with line shaft drive. All other groups with multi-motor DC-drive

Steam and Condensate System

Complete for all drying cylinders and air channel dryer, including all condensers, separators etc.

Starch Preparation System

Complete starch preparation and cooking system including all silos, tanks, agitators, screens, cooker, drives, pipes, valves, measuring and control instruments, drives and controls

Coating Colour Preparation System

Complete coating colour preparation system including all silos, tanks, agitators, screens, drives, pipes, valves, measuring and control instruments, drives and controls

FINISHING HOUSE

1 Slitter Rewinder

Make JAGENBERG, type VARI-DUR; operating speed 800m/min, with 10 slitters incl. unwind and all drives and controls

|

Spare Parts |

included as far as available |

|

Technical Documentation |

included as far as available |

|

Condition |

Machine was fully operational when shut in |