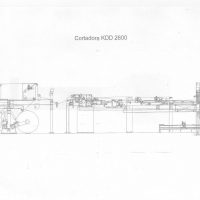

Complete Recycled Triplex Coated Cartonboard 2180mm, 45000 tpy

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10580

- Name: Complete Recycled Triplex Coated Cartonboard 2180mm, 45000 tpy

- Capacity: 45000 TPY

- Attachments:

RECYCLED TRIPLEX COATED CARTONBOARD

| Trim width | 2180 mm |

| Working speed | 50 – 220 mpm |

| Basis weight range | 150 – 650 g/m2 |

| Production | 45000 Tn/year |

| Average | 190 Tn/day |

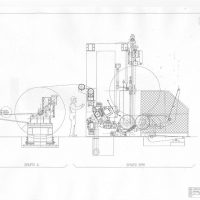

STOCK PREPARATION

FIBER FLOW PULPER (Ahlstrom 1995) of middle layer

Botton layer

* Low density AP-10 pulper

* Contaminex– Turboseparator ATS 12

* Vibrating screen Voith 1975

White top layer

* Lamort helical pulper 10 m3 (1982)

Bottom layer

* Voith hot dispersion (1975)

High density cleaner

* S-3 Voith in botton layer (1978)

* Lamort in middle layer (1997)

* Escher Wyss in white top layer (1975)

Turbosorter Voith of 0,65 mm slots (1985) of middle layer

Pressure screen of botton layer

* C-300 of 3 mm diam.

Basket (Licar 1971)

* Fibericer of 3 mm diam. holes (Escher Wyss 1981)

Pressure screen of white top layer

* Moduscreen C4R to Andritz of 3 mm diam. basket (2001)

* Maule hot dispersion (1974) of middle layer

* Voith hot dispersion (1975) of white top layer

Pressure screen of bottom layer

* F-20 Andritz (2001) of 0.25 mm slots basket

* F-10 Andritz (2001) of 0.25 mm slots basket

White top layer

* Vibrating screen ME-10 of Licar (1982) of 5 mm diam. holes

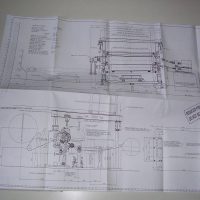

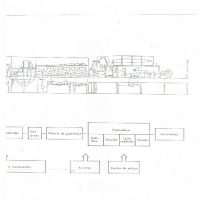

COATED BOARD MACHINE

| Trim width | 2180 mm |

| Working speed | 50 – 220 mpm |

| Basis weight range | 150 – 650 gsm |

Composed of the following elements:

* 3 Hogenkamp air cushion headboxes with manual adjustment

of lip

* 3 Forming wires (Voith 1977, Blanes 1984 y DG 1971)

* 1 DGI top former (DGI 1998)

* 1 transporting felt (Blanes 1971)

* 1st Suction press with top and bottom felt (DG 1977)

* 2nd and 3rd DGI Tem-Sec press (DGI 1989)

* Predrying section with 22 dryers of 1.500 mm. diam.:

* 16 Dryers of 2.400 mm. at 3,5 Kg./cm2

(Blanes 1971, DG 1977 y Gorostidi 1965)

* 6 Dryers of 2.400 mm. at 5 Kg./cm2 (DG 1977)

* Yankee cylinder of 2.400 mm. face x 4.000 mm. diam.

3 Kg./cm2,with high efficiency hood (Maquinista 1965)

* Inclined size-press of 500 mm. diam. x 2.500 mm.

face(Gorostidi 2000)

* Postdrying section with 12 dryers of 1.500 mm.

diam. x 2.400 mm. face, 3,5 Kg./cm2

(Blanes 1971,DG 1977 y Gorostidi 1965)

* 1st Calender stack with 3 fixed crowning rolls

(Gorostidi 1965)

FOR MORE INFORMATION PLEASE DOWLOAD THE ATTACHMENT!!

(Pictures of all sections and detailed technical information)