Paper machine 2.85m, 54-250 g/m2, 150t/d

-

Print this page

- Product ID: VAK11126

- Name: Paper machine 2.85m, 54-250 g/m2, 150t/d

The paper machine is equipped to manufacture different paper grades for the printing and writing segment. Coating base paper was the main product manufactured in this machine during the last years.

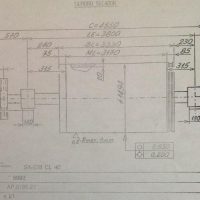

- Width: 2.85 m.

- Max. speed: 590 mpm.

- Basis Weight range: 54 -250 gr/m2

- Production rate: 150 Ton/día

- Bill Blade max.: 12 gr/m2.

VIDEO WITH INTRODUCTION TO THE MACHINE!

Drives and Control System:

- – DCS – Foxboro IA + Allend Bradley PLC network.

- – 2 Accuray ABB scanner, basis weight, caliper, mositure, ash, formation.

- – Web Inspection System by Honeywell.

- – Automatic CD profile control for Basis Weight, Voith Profilmatic with moduleLip, stepper motor actuators.

- – Automatic CD profile control for Caliper, with Honeywell Calcoil, induction control.

- – Automatic CD profile control by Honeywell, Devronizer steam box over the press section.

- – Regeneratives drives with AC induction motors:

- – Drives, ABB ACS800

- – ABB M3BP Motors.

- – Flender Gearboxes.

- – Hilliard disk brakes.

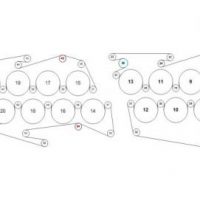

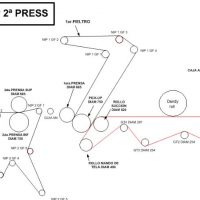

Forming board and press section:

- Dandy Roll

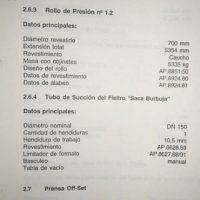

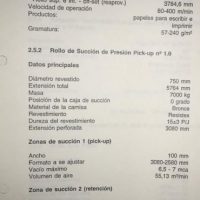

- Prensa Pick-up

- Primera Prensa

- Segunda Prensa

- Prensa Offset

- Bombas de vacío Voith 14E

- Steam box installed on the 1st press section.

-

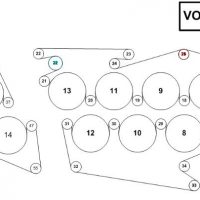

The 1st stage of steam dryer cylinder has 21 cans, is a Voith brand group.

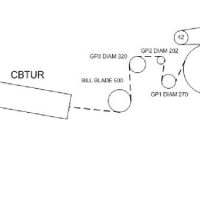

After the 1st stage of dryers the machine has a ABB Accuray scanner to measure the paper important properties, next it has a Bill Blade coater.

Then the paper is tranported through a air CB-Turn, to the Krieger Infra Red system. The Krieger emitter are the K6500 metallic model.

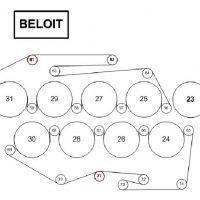

Calender

The Honeywell Calcoil CD control system is installed on the Hunt & Muscrop Calender.

After this control equipment, is installed the 2nd ABB Accuray scanner and a Honeywell web inspection system.

Pope reel change is fully automatic.

Original manufacturer of machine and manufacturer year..

- 1995, The machine was totally upgraded by Voith.

o Headbox, with Profilmatic Module Lip Basis Weight control.

o Forming section

o Press Section

o Vacuum pumps.

o Drives.

o DCS.

o Dryers.

o Pope Reel control, Voith.

o Calender, Hunt & Moscrop.

o Air circulation.

o Krieger IR dryers.

o Bill Blade size press.

o QCS Accuray ABB, two scanners.

Main rebuilds / moderizations and years ?

- 2005, Regenerative Multidrive from ABB ACS800 to control motors suction roll, couch, presses, dryers, calendar, rolls,…

- 2007, Cross Direction profile controls:

o Calcoil, from Honeywell to control the caliper by induction heating over the calendar.

o Devronizer, steam box from Honeywell to control de moisture profile.

o Rexroth new hydraulic control system for pope reel movements.

o Drives upgrade, replacing old Telemecanique drives and ACS600 from ABB, installing ABB ACS800.

Voltage frequently of motors

- 500 V / 50 Hz

Machine

- Stopped since January 2017.

Bars of Drying cylinders

- Could operate at 6 bar, however the pressure in MILL used to work at 4 barg max.

DCS, QCS

- DCS, foxboro IA.

- QCS, ABB based on the DCS800xA, with scanners Accuray Smart Platform 1200, moisture, caliper, ash, formation, basis weigth, brightness sensors.