Paper Machine Liner-Fluting 5160mm, 150.000 tpy, Valmet

-

Print this page

- Product ID: VAK10353

- Name: Paper Machine Liner-Fluting 5160mm, 150.000 tpy, Valmet

- Year: Original start-up 1961, many rebuilds until 2005

- Country: Finland

- Capacity: 150.000 TPY

MACHINE HAS BEEN USED TO MAKE MFC, AND IT IS SOLD ONLY TO PRODUCE KRAFT PAPER !!

COATER AND CALANDER ARE NOT INCLUDED !

Liner-Fluting Paper Machine

Capacity 150.000 t/a

Speed 1250 m/min

Trimmed width 5160 mm

MFC 51 g – 70 g

Furnish

Chemical pulp 28-44 %

PGW

Ash content 6 – 10 %

Rolls, wire section

Wire lead roll:

D=565 mm, L=6000 mm, c/c Bearings = 6400 mm

Breast roll:

D=828 mm, L=6000 mm, c/c Bearings = 6400 mm

1st former roll:

D=1123 mm, L= 6050 mm, c/c Bearings = 6650 mm

2nd former roll:

D=960 mm, L= 6000 mm, c/c Bearings = 6400 mm

Bottomwire drive roll:

D=828 mm, L= 6000 mm, c/c Bearings = 6400 mm

Topwire drive roll:

D=812 mm, L= 6000 mm, c/c Bearings = 6400 mm

Couch roll:

D=1125 mm, L= 6000 mm, c/c Bearings = 6900 mm

Rolls, press section

1st press deflection compensated roll

D=605 mm, L= 6050 mm, c/c Bearings = 7000 mm

Press suction roll

D=1061 mm, L= 6000 mm, c/c Bearings = 6900 mm

3rd press ZS-1 roll

D=670 mm, L= 6050mm, c/c Bearings = 7000 mm

Center roll

D=1255 mm, L= 5950 mm, c/c Bearings = 6900 mm

Felt lead roll

D=513 mm, L= 6060 mm, c/c Bearings= 6550 mm

Pick-Up suction roll

D=800 mm, L= 6000 mm, c/c Bearings = 6756 mm

Spreader roll

D= 260 mm, L= 6100 mm, c/c Bearings = 6650 mm

Rolls, press section

D= 550 mm, L= 5910 mm, c/c Bearings = 6810 mm

Drying section

D= 440 mm, L= 6000 mm, c/c Bearings = 6360 mm

D= 440 mm, L= 5810 mm, c/c Bearings = 5950 mm

D= 440 mm, L=5880 mm, c/c Bearings =6155 mm

Disc filter

Enso IKS 38-14,5 1986

Capacity

70 tpd

250 l/s

14 discs, d=3800mm

Filtering area 280 m3

Filtrates

Cloudy, Clear

Chemical pulp refiners

Emerson–Claflin 303 3 pcs (1981)

Machinery

Vacuum pumps, NASH

904 – T2 400 kW 1989 5 pcs ( three available, possible to get compensate 9002 model )

904 – P1 315 kW 1989 1 pc

904 – P2 250 kW 1989 1 pc

Individual drives for pumps

On-line measurements

Cationic demand, Metso’s CATi for white water ( not available )

Retention control, Metso’s RMi for white water and headbox ( not available )

Air measurement, Savcor’s Conrex, bubble air

Consistency

Metso’s MCA and BTG 2300

Flow meters

Fisher Porter, ABB, Krohne

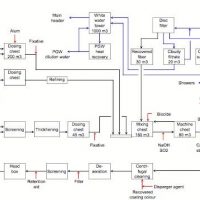

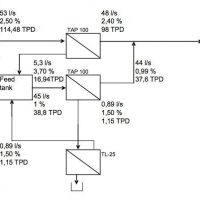

Short circulation

Centri cleaners (1988 )

Ahlström 6 stage centri cleaners, Twincleaner 133

Atrex dispergator 700 CD for 6th stage reject handling

50 – 100 % is feeded back to 2nd stage

1st stage feed 1500 l/s, c=0,805 %

6th stage reject 4,7 l/s, c=2,016 %

Machine screening

Two Jylhävaara’s JS280 (1986 ) primary screens, hole dia 1,6 mm, 1340 l/s

One Metso’s TAS 200 ( 1995 ) secondary screen, slot 0,2 mm

Deculator

Ensovac ( 1987 )

Retention aid preparation and screening

Retention aid , PAM

PM has it’s own slurry making device supplied by Allied Colloids

retention aid is delivered in 500 kg bags

3 m³ dissolving tank

15 m³ storage tank

Two automatic slot screens supplied by Allied colloids

Paper machine production technology

Basepaper machine ( start up 1961 )

Bottom fabric width 5860 mm

Sym-flo headbox ( 1986 )

Flow width 5670 mm

Sym-former R ( 1985 ), modernised fourdrinier

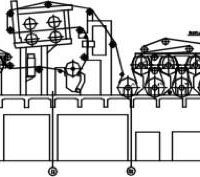

Sym-press II 70/80/100 kN/m ( 1989 )

steambox

Center roll ; Valrok C , Ceralease S

Sym ZS –roll 3rd

Suction roll cover ; poly-urethane, Press-Bison ( Metso)

Double doctors at center

Tail-threading: tail shooter

1st & 2nd nip, hydraulic load controls by Rexroths digital

HNC-100 controllers

Suction transfer roll ( new )

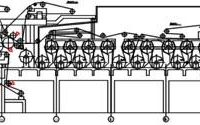

Drying section

33 drying cylinders and 10 vac rolls, cyl. dia 1500 mm

two single felt groups ( cyl.1-21) with 5 HI-Run boxes and 5 HS-boxes ( Hi-Run new )

two twin-run groups ( cyl. 22 – 43 )

Tail-threading : single groups with air pipes and twin-run groups with ropes

steam pressure 350 kPa

Reeler

Pneumatic reel

Reel cylinder, Trackmate cover

D=1100 mm, L=5630 mm, Lv=6330 mm

tail-threading; doctorblade frame airblow

spool dia 550 mm

Paprima highspeed slasher ( 2005)

Winders

Jagenberg VariStep 65

Metso WinRoll 1997 (NOT complete )

Salvage winder

Wrapping machine

RollPack (Plastic wrap)

Accuray process control system ( 2004 ) ( Not complete )

1 x Accuray NEXUS (PM)

6 scanners , Smart Platform

– 6 x IR Hemi + (moisture)

– 6 x STLK11 (BW)

– 3 x Caliper GT

– 2 x 2-componet ASH

Profile actuators

1 x Steambox (pneum. actuators ,PM)

– 2 x ABB Induction profiler (caliper, PM)

– Metso Jetmatic MT ( slice )

DCS Metso XD (2000), DNA (2004) ( Not complete )

Break camera system; Hilcont 500 D ( 16 cameras ) Not available

Ulma NTi hole detector system on basepaper (2005) Not available

and before the reel

THIS PAPER MACHINE WILL BE SOLD ONLY TO PRODUCE KRAFT PAPER AND WILL BE SOLD WITHOUT COATING UNIT AND CALENDERS !