Valmet Paper Machine, 7270mm 250.000 tpy

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10363

- Name: Valmet Paper Machine, 7270mm 250.000 tpy

COATER AND CALANDER ARE NOT INCLUDED !! BASIC DATA

Capacity 250.000 tons / a

Trimmed width 7270 mm

Speed 1330 m/min

LWC offset 60- 80 gsm ( 90 gsm ), average 68 gsm

Cote , Cote Silk, Ultra, Ultra Silk grades

Furnish

Chemical pulp 26 – 34 %, CSF 620 ml

PGW mechanical pulp , CSF 60 ml ( PGW70 )

ash content 8 – 12 % in basepaper

Fillertalc, F15

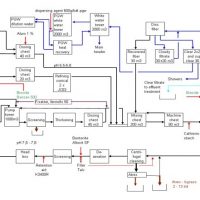

SHORT CIRCULATION

Centri cleaners (1988 )

Ahlström 6 stages centri cleaners, Twincleaner 133, 1.stage feed 1650 l/s

5 th and 6 th stage has Andritz Vortex nozzles for reject dilution

Atrex dispergator ( CD 700 ) for 6th stage reject handling

50 – 100 % is feeded back to 3rd stage

Base paper ash content limits reuse of 6th stage reject 60 – 65 gsm

Machine screening

Two Jylhävaara's JS400 (1988 ) primary screens, hole dia 1,6 mm, 1650 l/s

One Metso's TAS 340 ( 1995 ) secondary screen, slot 0,2 mm,

reject is handled in a broke system

Retention aid is infed after screens with trump jet ( 4 nozzles )

Deculator

Clark & Vicario 1968

White water saveall, disk filter ( 2002 )

Supplied by GL&V, type VDF 5,2 x 9/14 – 325

14 disc , dia 5,2 m

RETENTION AID PREPARATION AND SCREENING

Bentonite ( all PM's )

Silo 50 m³ or 500 kg bag system

slurry preparation is supplid by Allied Colloids, continuos process

5 m³ storage tank

Bentonite is filtered with two automatic changed slot screens supplied by Allied Colloids

Retention aid , PAM

PM has it's own slurry making device supplied by Allied Colloids

retention aid is delivered in 500 kg bags

3 m³ dissolving tank

5 m³ storage tank

Two automatic slot screens supplied by Allied colloids

Trump jet infeed system with 4 nozzles

ALUM DISSOLVING UNIT

Silo 68 m³ or 500 kg bag

Screw conveyors

3 m³ mixer , batch process

2 x 12 m³ storage tanks

Supplied by JylhäRaisio ( Metso )

MACHINERY

Vacuum pumps, NASH

904 –T2 400 kW 1987 2 pcs

CL 9001 G 1967 1 pc

CL 9002 G 1967 5 pcs

Individual drives for pumps

On-line measurements

Cathionic demand, Metso' s CATi for PGW and white water

Retention control, Metso's RMi for white water and headbox

Air measurement Savcor's Conrex for bubble air

Consistency

Metso's MCA for PGW, Pulp, machine stock

Flow meters

Fisher Porter, ABB, Krohne

PRODUCTION TECHNOLOGY

Basepaper machine ( start up 1968 )

Bottom fabric width 8050 mm

Sym-flo headbox ( 1987 )

Sym-former R ( 1984 ) , modernised four-drinier

Sym-press II + 4 th press 70/80/105/120 kN/m ( 1988 )

Valmet steambox ( 1998)

Center roll ; Valrok C , Ceralease S

4th press roll; Valrok Standard

Sym ZS –rolls 3rd and 4 th press

Suction roll cover ; poly-urethane ( Stowe )

Double doctors at center and 4th press roll / Valmet

Tail-threading: tail roll and tail shooter

Drying section

38 drying cylinders and 7 vac rolls, cyl. dia 1500 mm

two single felt groups ( cyl.1-15) with 3 HI-Run boxes and 4 HS-boxes

three twin-run groups ( cyl. 16 – 45 )

Ropeless tail-threading : single groups with air pipes and twin-run groups with Metso's new double force system ( belt tail-threading)

steam pressure 350 kPa

automatic hood ventilation control

PAPER MACHINE ROLLS

Wire section

Lead rolls , D= 664 mm , L= 8150 mm, Bearing clearance= 8650 mm

Breast roll, D= 990, L=8100, BC = 8650mm

1st former roll, D=1200, L= 8200 mm, BC= 8850 mm

2nd former roll, D=990 mm, L= 8100mm, BC= 8100 mm

Bottom wire drive roll, D= 990 mm, L=8100mm , BC= 8570 mm

Top wire drive roll, D= 990mm, L= 8100 mm, BC= 8650 mm

Couch roll, D= 1210 mm, L= 8200 mm , BC= 9100 mm

Press section

Center rolls, D= 1375 mm, L= 8150 mm, BC= 9450 mm

Sym roll ( 1st press ) , D= 805 mm ( 925 mm) , L= 8100 ( 8450 ) , BC= 9100 ( 9300 )

Press suction roll , D= 1252 mm, L= 8200 mm, BC= 9450 mm

SymZS roll (8 zones ) , D= 805 mm, L= 8400 mm, BC= 9300 mm

Lead rolls, D= 664 mm, L= 8250 mm, BC= 9150 mm

Pick up suction roll, D= 1047 mm, L= 8250 mm, BC= 9300 mm

Spreader roll, D= 353 mm, L= 8320 mm, BC= 8920 mm

Drying section

Lead rolls D= 504 mm, L= 8100mm , BC= 8700 mm

Lead rolls, D= 554 mm, L= 8100 mm , BC= 8700 mm

Optireel cylinder

D= 1500 mm, L= 7950 mm BC= 8650 mm

PRODUCTION TECHNOLOGY

Reeler

Optireel Plus ( 1999 )

IQ-tension measurement

edge slitters

tail-threading; foil-force by Metso ( 3 belts )

spool dia 720 mm and a parent reel dia 2700 mm max.

Winders

JR 1000 ( 1988 )

Reel max dia 1500 mm, max width 3200 mm

6 pcs 4 ton and 4 pcs 6 ton stations

Twin winder ; center drum winder ( 1982)

max dia 1300 mm, max width 2600 mm

max reel weight 3 tons

Salvage winder

JR 300

max reel weight 6 tons

max dia 1500 mm, max width 3200 mm

Wrapping machine

conventional craft ( modernised several times )

max dia 1500mm, max width 3200 mm

Accuray 1190 process control system ( 1999 )

6 scanners , Smart Platform

- 6 x IR Hemi + (moisture)

- 6 x STLK11 (BW)

- 3 x Caliper GT

- 2 x 2-componet ASH

Profile actuators

Metso Steambox (electric actuators)

- 2 x Metso Coatmatic (Coatweight)

- 1 x IRT Infra dryer (Moisture)

- 1 x Impact Thermajet (caliper )

XDi DCS system ( 1999 )

Break camera system; Hilcont 500 D -> Proweb( 28 cameras ) (2003 )

Ulma nt hole detector system on basepaper ( 1999 ) and 3D-Ulma on the reeler

Maintenance monitoring system ( 1999 / 2005 )

Sensodec 6S

felt monitoring

pulsation 6 measurement units

vibration 460 measurement units

lubrication MACHINE HAS BEEN USED TO MAKE LWC, AND IT IS SOLD ONLY TO PRODUCE KRAFT PAPER!!!

COATER AND CALANDER ARE NOT INCLUDED!