Valmet Paper Machine 8620mm, 650 tpd

-

Print this page

- Product ID: VAK10818

- Name: Valmet Paper Machine 8620mm, 650 tpd

- Capacity: 650 tpd

- Manufacturer: VALMET

- Attachments:

TECHNICAL DATA:

Built 1982

Trimmed width: 8620 mm

Max. operational speed: 1350 m/min

Annual production: 225.000 tpy

Paper grade: News Print and Teledirectories

Investments

•Winder modernisations Winder 42 year 1997 and Winder 41 year 2001

•PM4 1300 m/min project (for PM speed up) during year 2000

•Also other minor improvement investements during operation years

Short and water circulation and broke system

Short circulation

•Process pumps by Ahlström

–Headbox feed Ahlström ZXX-70, 2200 l/s, 42 m

•(4 machine screens) + Secondary and Tertiary screens

–4 Jylhävaara JS-280 (basket 1.6 mm hole) + JS-120 + JS-30

•Ensovac Deaerator

•Enso Twincleaner 132 in 5 stages

Water circulation

•Disc filter by GL&V Hedemora Ab: VDF 5.2 – 28 type from year 2000 Broke system•Press and machine pulper Jylhä Lowpulper JP-31D and JP-34D types with 2 rotor units + couch pit and winder pulpers

•2 broke Andritz MODUscreens and broke deflaker JJF-250 by Jylhävaara

PM rolls, forming fabrics, press felts and drying fabrics

•Bottom and top wire fabrics

•Pick up felt

•1. and 3. press felts

•3 single tear drying fabrics

•4 douple tear drying fabrics

•12 wire section rolls 26 press section rolls 43 drying cylinders (incl Vacs) 70 drying section other •rolls 3 calander rolls + 4 other rolls reeler cylinder + spools

Head box

•Conventional SymFlo head box from year 1987 by Valmet

•Slice width 9120 mm, Jetmatic slice lip control with 74 Actuators

•Slice opepening controlled with horizontal and vertical movements

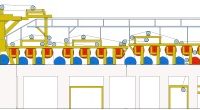

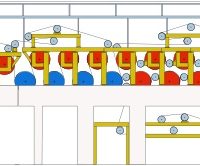

Wire section

•Symformer N type wire section by Valmet

•Forming roll, Vacuum foils – 3 units, Multifoil shoe and Flatboxes – 3 units

•Vacuum system with Ahlström CL 9001 G and 9002 G type water ring pumps, 10 units

•Retention control through wire water consistency control

•Head box feed consistency ~ 0,95 % and after wire section paper web solids ~ 16 %

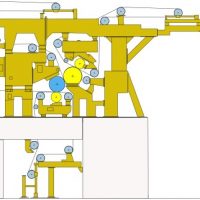

Press section

•Valmet SymPress with 3 loading nips and felts

–Ku?sters rolls in 1. and 3. press positions

–Centre roll Dynarok and spare roll with ceramic cover PressGem W (used only 3 months) by Metso

–Line loads 60, 80 and 127 kN/m

•Devronizer steam box by Measurex with moisture profiling capability

–position after 1. press

–steam flow of up to 1.6 kg/s

–60 control valves

•Solid content after press 43 %

•Short distance in open draw between press and drying section

•Sensodec vibration monitoring system

•Felt guide roll system (Double force)

•Hilcont break camera system

Drying section

•5 drying groups

–Cylinder diameter 1830 mm, 32 pcs

–Cylinder max. pressure 5 bar overpressure

–Hydraulic stretchers

•Dryer section parts 1-3

–VAC cylinders in first three groups

–Hirun 2000 runnability devices in first drying groups

–Ropeless tail threading system

–Dryer fabrics cleaning system + local controls in the field

•Dryer section parts 4-5

–Double felted groups

–Web tail threading with FoilForce by Valmet

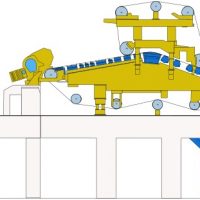

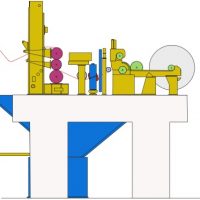

Machine calander and reeler

•Conventional hard nip machine calander with 3 rolls

–Loading range 60 – 120 kN/m

–Calcoil caliber control system (118 units)

•No quality measurement beam

•Ulma hole detector system

•Conventional pope reeler

–Reeler tail threading with blower

–3 to 5 sets per reel, max 2.7 m

•Parent roll carriage + reel stands

•Design width at reeler 8,72 m

Winders

•Originally Ahlström KL 1000 two drum winders from 1982

–Max design speeds, Winder 1 2300 and Winder 2 2500 m/min

–Max roll diameter 1500 mm

–Max number of reels 14

–Max deckle width 8620 mm

–Tension control system Eilersen

•Winders rebuilt in investments during years 1996, 1997 and 2001

–Modernisation to Valmet Winair type with Wincontrol

–Slitter and spreading section renewal

Auxiliary systems

•Lubrication and hydraulic systems

•Heat Recovery systems for Hood ventilation

•Distribution transformers (10 kV => 693 V and 525 V)

•MCC´s, variable speed and DC drives

•Process pumps and motors

•Field instrmentation (automation valves, flow meters etc…)

•Winders MCS (Siemens S5 (Wi2) and S7 (Wi1)

•Machinery specific spare parts

•All existing documentation (manuals and 15 000 electric soft copies)

Excluded

•Air compressors

•Process control automation system (QCS and MCS, DCS)

•Cables

•Cranes

SCOPE DESCRIPTION

| EQUIPMENT | INCLUDED | EXCLUDED |

| Head box | X | |

| Wire section | X | |

| –Frame structure | X | |

| –Rolls incl available spare rolls | X | |

| –Dewaterig elements | X | |

| –Wire stretchers and guides | X | |

| –Shower pipes | X | |

| –Doctors | X | |

| –Steel structures incl service platforms | X | |

| –Available existing spare parts | X | |

| Press section | X | |

| –Frame structure | X | |

| –Rolls incl available spare rolls | X | |

| –Felt suction bo es | X | |

| –Steam bo | X | |

| –Felt stretches and guides | X | |

| –Shower pipes | X | |

| –Doctors | X | |

| –Blow bo | X | |

| –Steel structures inc service platforms | X | |

| –Available e isting spare parts | X | |

| Dryer section | X | |

| –Dryer cans | X | |

| –Felt rolls incl available spare rolls | X | |

| –Felt stretches and guides | X | |

| –Doctors | X | |

| –Runnability components | X | |

| –Tail threading equipment | X | |

| –Tail cuttter | X | |

| –Hood ventilation | X | |

| -Small part of Hood | X | |

| -Air blowers | X | |

| -Heat e changers | X | |

| -Air ducts | X | |

| –Steel structures incl service platforms | X | |

| –Available e isting spare parts | X | |

| Calander | X | |

| –Frames | X | |

| –Rolls | X | |

| –Calcoil | X | |

| Reel | X | |

| –Reel drum | X | |

| –Tail threading equipment | X | |

| –Spools | X | |

| –Steel structures incl service platforms | X | |

| –Available e isting spare parts | X | |

| Winder | X | |

| two winders | X | |

| Available spare parts | X | |

| Rewinder | X | |

| Broke splitter with pulper | X | |

| Pulp and water handling | X | |

| –Disc filter for white water cleaning | X | |

| –Pipes for disc filter for reasembling | X | |

| –Broke thickener | X | |

| –Broke screens | X | |

| Winder base plates | X | |

| PM grease lubrication system incl pipes | X | |

| PM oil lubrication system incl pipes | X | |

| PM + winder hydraulic system incl pipes | X | |

| PM + winder pneumatic systems incl pipes | X | |

| PM mechnical drives | X | |

| Parent roll carriages and stands + PM platforms | X | |

| PM (press + reel) + winder pulpers incl pumps | X | |

| PM steam and condensate system incl pipes | X | |

| -pipes for reasembling as a same | X | |

| PM vacuum system incl pipes | X | |

| -pipes for reasembling as a same | X | |

| PM approach system incl pipes | X | |

| -pipes for reasembling as a same | X | |

| PM heat e changers | X | |

| PM water filters | X | |

| Pulper exhaust fans incl air ducts | X | |

| Overhead cranes | X | |

| Air compressors | X | |

| Machine hall ventilation equipment | X | |

| Room ventilation equipment | X | |

| Core handling (saw + conveyers + crane) | X | |

| Tanks and storage towers | ||

| Tanks with agitators | X | |

| Storage towers (>1000 m3) | X | |

| Process pumps | X | |

| Pipes + handvalves | X | |

| Part of process pipes and supports | X | |

| Fire fighting pipes with handvalves | X | |

| Electric equipment | ||

| distribution transformers | X | |

| MCC’s | X | |

| –Motors (as on the field) | X | |

| –Variable speed drives | X | |

| –electric drives | X | |

| –cables | X | |

| –Specific available spare parts | X | |

| Automation equipment | ||

| –Automatic valves | X | |

| –On line special measuments | X | |

| –Field instruments | X | |

| –MCS systeem | X | |

| –DCS system | X | |

| –QCS system | X | |

| –Special automation system | X | |

| -ULMA hole-detector | X | |

| -Hillcont break camera system | X | |

| –Cables | X | |

| –Specific available spare parts for | X | |

| special automation system |