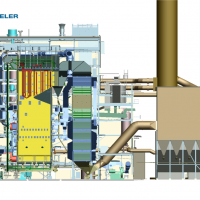

Power Plant BFB-Boiler (2001) 88MW

-

Print this page

- Product ID: VAK11184

- Name: Power Plant BFB-Boiler (2001) 88MW

Video tour of the site in the end of technical description. Filmed January 2020

NO RESTRICTIONS ON SALE

BFB-boiler

- 88 MW

- Foster Wheeler 2001

- 33,5 kg/s, 90 bar (36 kg/s,115 bar), 525 C

- Running time: 88 000 hour

- Latest revision in 2009 (air preheater)

- Maintenance revision annually

- Operation manual in Finnish

Main Fuels:

– Bark, saw dust, wood chips and waste wood, peat.

–Sulphur <0,05%

–Moisture 30-65%

–LHV 3,7-6,9 MJ/kg

–Peat

–Sulphur 0,25%

–Moisture 40-58%

–LHV 6,3-11,3

Sludge from WWTP

–Sulphur 0,2-1,7%

–Moisture 65-75%

–LHV >0,5MJ/kg

–max. 7% of fuel power

Included:

- main machinery and key components

- feed water pumps and motors 2 pc

- high-pressure preheater, feed water heater

- feed water valves

- injection water system

- steam drum

- combustion chamber

- fuel drop funnel 4 pc

- start-up burners 2 pc

- load burners 2 pc

- waste oil burner, waste oil tank

- natural gas filters

- economiser

- air-preheater

- super heater

- exhaust system

- main steam valve

- safety valves

- dust removing system

- bed material system, bed sand silo

- bed sand preparing

- bed lime system, lime silo

- furnace ash system

- fly ash system, fly ash silo and screws

- primary air blower

- secondary air blower

- twist grip blower

- bag filter

- flue gas blowers 2 pc

- flue gas scrubbers, lye system, scrubbers sludge system

- safety locking system

- nitrogen preservation system

- chemicals dosage and chemical pumps

- sample system

- chimney

Solid fuel system for (NOT ALL AVAILABLE)

- Maintenance revision annually

- Raumaster, built in 2001

- Operation manual in Finnish

Excluded: Not available

- bar conveyor

- crusher

- fuel batching screw, fuel receiving pocket

- scraper conveyor to screen hall

- screen system

- scraper conveyor to silos and scraper conveyor on the silos

- peat silo, fuel batching screw (batching screw not existing)

- bio fuel silo, fuel batching screw (batching screw not existing)

- fuel line from silos

Included:

- fuel line 1 from SFS to the boiler

- fuel line 2 from SFS to the boiler

- back-up fuel pocket and fuel batching screw

- fuel batching screw at the power plant

- robbery fuel batching screw

- batching bin 2x50m3

- scraper conveyor at the boiler 2 pc

- fuel batching pockets and fuel batching screw

- fuel feeder 4 pc

- fuel sample crusher

- extinguishing steam system

Sludge system

- built in 2002

Excluded: Not available

- compressor

- sludge pneumatic press

- sludge pipe cleaning system

- blowpipe to the power plant

Included:

- cyclone

- sludge silo and batching screw

Automation and electrical equipment, spare parts.

Included:

- Alcont-control system

- field instruments (as it is on the field)

- motors

- frequency changers

- automatic valves etc. (as it is on the field)

- auxiliary devices (as it is on the field)

- all available existing specific spare parts

Excluded:

- Radioactive sources

Water treatment system at the power plant

- built in 2006

- YIT

- raw water purification and desalination

- operation manual in Finnish

Raw water purification

- max capacity: 146 m3/h

- capacity: 73m3/h

- min capacity: 11 m3/h

Included:

- pumps and compressors

- tanks

- flock-filtering system 2 pc

- preheater of raw water

- automation and electrical equipment (as it is on the field)

- motors

- frequency changers

- valves

- auxiliary devices (as it is on the field)

- all available existing specific spare parts

Desalination

- Net capacity: 2 x 72 m3/h

Included:

- cation exchangers 2 pc

- A1/A2 exchangers 2 pc

- MB exchangers 2 pc

- tanks

- pumps

- heat exchanger: dilution water of lye

- automation and electrical equipment (as it is on the field)

- valves

- motors

- frequency changers

- auxiliary devices (as it is on the field)

- all available existing specific spare parts

Steam, condensate and feed water system

Included:

- feed water tank

- condensation tank

- purification of condensation, precoat-system

- condensed steam pumps

- steam tanks

- steam condenser

- reduction valves

- steam-pressure accumulator

- cooling water system

- automation and electrical equipment (as it is on the field)

- valves

- motors

- frequency changers

Compressed air system (Not included)

- Keaser

Excluded:

- air compressor

- compressed air dryers

- tank

Common electrical equipment

- process central

- distribution transformers

- 1 pc 400 V 1,25 MVA

- 2 pc 690 V 3,15 MVA

- Steam Cylinder

- Hanging rods

- Sonic shootblowers

- Steam shootblowers

- Scraper conveyor left

- sludge silo

- Main steamvalve

- Scraper conveyor inside

- Scraper conveyor

- Fuel feeding pocket

- fuel feeders

- load burners

- fuel feeder

- fuel funnel

- fuel funnel’s air pipes

- stat-up burners

- feed water valves

- bed ash conveyor

- bed ash conveyor

- bed ash conveyor