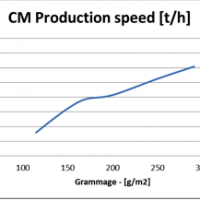

Offline Coater 3860mm, 115-300 g/m2

-

Print this page

- Product ID: VAK10756

- Name: Offline Coater 3860mm, 115-300 g/m2

OFFLINE COATER

Four blade coating stations

| Machine speed | 750 – 1050 m/min (designed 1200 m/min) |

| Grammage | 115-300 g/m2 |

| Reel width | 3860 mm |

| Jumbo reel diameter | 2400 mm |

| Jumbo reel weight | 19 t |

| Jumbo reel + bar weight | 22 t |

| Drive power | 400 V |

| Drive side | Left in paper run direction |

| Machine length | 94 m |

1 Unwinder

Valmet (1989)

Automatic splice from full speed

Max diameter 2400 mm

2 1st stage coating with coating stations 3 and 4

Valmet Auto Blade

- Automatic MD-coatweight control (Autoblade constant tip angle)

- Automatic CD-profiling with Procoat (2002)

Drying

- Electric IR, Compact 1300 kW (2009)

- CD moisture control

- Three air dryers

- Power Float+ nozzles (2009 and 2011)

- 11,5 bar steam heated

Automatic backing roll cleaner on 4th station

AC drives at middle layer coater (ABB ACS 800, 2011)

3 2nd stage coating with coating stations 5 and 6

Jagenberg Combi blade

- Automatic MD-coatweight control with blade angle

- Manual CD-profile control

- Automatic backing roll cleaning on both stations

Drying

- Electric IR, Itronic 2080 kW

- CD moisture control

- Three air dryers

- 11,5 bar steam heated

- After 5th station 5 drying cylinder (used with low grammages < 200 g/m²)

Before reeler

- 2 drying cylinders, but not used

- 2 cooling cylinders

- Water cooling, temperature 27 °C

DC drives at top layer coating section

4 Reeler

- Automatic jumbo reel changeover with TUSA Standar III

- Soft reel drum

- Akhydril G rubber

- Hardness P&J 10 ±2

5 Steam and Condensate systems

- 11,5 bar steam for air dryers

- 3,5 bar steam for drying cylinders

6 Air systems

- Heat recovery for exhaust airs

7 Control Systems

7.1 QCS

Honeywell DaVinci (2001)

Five frames (HW 4000 Precision Scanner)

- Unwinder

- Basic weight, moisture

- After 3rd, 4th, 5th, 6th coating stations

- Basic weight, moisture and coat weight (calc.)

7.2 DCS

Honeywell

- Middle layer coating (3rd and 4th stations)

- Alcont 1

- Top layer coater (4th and 5th stations)

- Total Plant Alcont

- Master

- Total Plant Alcont

7.3 MCS

Siemens S7-400 (2009-2011)

7.4 Coating Kitchen

- Control system licenses and some PCs are owned by third part suppliers

- Cranes are not included in the scope, but can be used during demolition

- Cables are not included in the scope (should be cut after safety switch)

- Most of the documents are in electronic format

Old docs in GP4-format (images) and new docs in DWG-format (AutoCAD) - Machine specific spare parts are included in the scope,

rest spare parts will be clarified later on

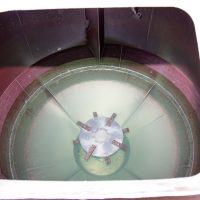

Mixers

- Cellier

- 2x 7m³ mixers. One for 1st stage coating and other for 2nd stage coating.

- 2x Scales for coating components

Screening with shaking sieves

- Cellier

- 6 for 1st stage coating, 6 for 2nd stage coating and 4 for clay

Clay elutriator with silo and conveyors

- Cellier

- Silo 60 m³ and discharge equipment’s

- Own scale for clay

- Mixer, 16t dry Clay for one batch

- Motor 6 kV

Ultrafilter

- Valmet

- Shaking sieve and pressure screen before ultrafilter

- Capacity 7,5 m³/h, concentrate solids 30-35%

- 60 membrane packs, filtrate area 60 m²

CMC silo

- 21 m³

- 2x scale and discharge screw

Starch silo

- Silo 70m³

- Cooker not available!!!

DCS

Honeywell Total Plant Alcont (2001)

- Common with DCS of the off machine coater’s