Recycled fibre line (RCF) Capacity – 1000 ADT/d (build 2003)

-

Print this page

- Product ID: VAK11242

- Name: Recycled fibre line (RCF) Capacity – 1000 ADT/d (build 2003)

RCF3 Key Facts

- Manufacturer – Voith

- Start Up – 2003

- Capacity – 1000 ADT/d

- Raw Material – 100% recycled fibre

- Overview Process Facts

- Continuous Process (Drum Pulper)

- 2 Loop Process

- “Tankless” system

- Upgraded Voith energy saving flotation – using variable speed drives controlling from pressure

- Using Metso DCS control and quality control system

Conveyor system

- Bale System

- Dewirer

- Bale breakers

- Loose Conveyor

- Loading conveyor

Both above raw material handing systems feed onto one conveyor and into a levelling drum before transferring onto the feed conveyor

- Feed Conveyor

- Rubber belt

-

- Feeds directly to the drum

Pulping

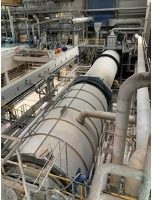

• Pulper – Andritz Fibreflow (FF-400)

- Length 7 m

- Chemical and steam addition at pulping

• Pulper – Andritz Fibreflow (FF-400)

- Length 7 m

- Chemical and steam addition at pulping

- Dump Tower 1 and 2

- 800 m3 per tower

Cleaners (Voith HydroClean)

- 4 Stages of Cleaners

- Cascade system

Fine screening

- 4 Stages of Fine Screening

- 1st Stage – MSS 18/16

- 2nd Stage – MSS 12/15

- 3rd Stage – MSS 08/08

- 4th Stage – MSS 08/05 + Andritz Dolphin Rota upgrade

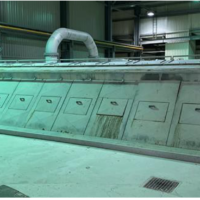

Voith Flotation (pre&post)

- Pre-Flotation

- 2 Stages (Primary and Secondary)

- Primary Cells * 5

- Secondary Cells * 3

- Post-Flotation

- 2 Stages (Primary and Secondary)

- Primary Cells * 4

- Secondary Cells * 2

Primary Cells in both Pre and Post flotation are upgraded Voith VSD Low Energy flotation injectors and supply pumps

Disc Filters (Thickening)

- Loop 1 and Loop 2 Thickening

- Manufacturer – GL&V Hedemora VDF

Screw Press and Disperger

- SCP1910MM Andritz Screw Press

Disperger

- Andritz CompDis CD13