STRECKER BRUDERHAUS 1450mm SYNCHROFLY SHEET CUTTER

-

Print this page

- Product ID: VAK11131

- Name: STRECKER BRUDERHAUS 1450mm SYNCHROFLY SHEET CUTTER

Basic info

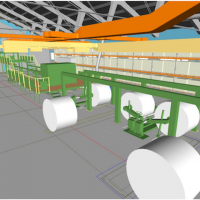

- Strecker Bruderhaus number 1938 with two delivery sections (Secondary belts & layboys).

- Year of origin: 1976

- Full repairing and modernization in 2007-2008

- Net width 1450 mm

- Synchro cross cutting capable for board and paper. Board specially for < 400 gsm and paper of 50 gsm – 240 gsm.

- Electrical sheet length changing system length 400 -1700 mm.

- Electric sheet length control +-0,2 mm Constructional speed 250 m/m. Vacuum overlapping section.

- Reject gate Pallet change

- Layboy

- Tab Inserters

- Slitters Unwind

- Lead roll system

- De curling units Electric

- Side trim system Condition

- Faulty sheets can be run into reject gate

- Auto non-stop pallet change system. Continuous

- running during the pallet change.

- 2 pcs of new layboys with 4 side joggers and back board. Sinking hydraulic layboy with capacitive sensor for pallet height. .

- 4 Tab Inserters

- Three (3) slitters. .

- Six (6) shaft less Strecker – unwind stands.

- Air cooled disc breaks with pneumatic adjustments. Reel core 3-6”, reel width 1530 mm, reel dia 1500 mm, reel weight 2000 kg.

- Complete lead roll system for paper.

- De curlers for paper, rolling bars, dia of 10 mm

- Electric system 380 V 50 Hz. PLC Siemens S5 Complete side trim system with shredder, tubes and blower.

- The line has been dismantled by KSF in excellent condition, packed well and loaded into 4 containers for the very accurate re-erection.

- Any special overhauling or repairing are not needed.

COMPLETED RENOVATIONS, IMPROVEMENTS AND MODERNIZATIONS IN 2007- 2008

The entire production line was thoroughly repaired, all defective parts replaced or repaired free from defects. In addition to this was made the next improvements and / or upgrades:

- Unwind stands

- The new web tension control was built controlled by PLC and smart relays.

- Arms of the unwind and roll lifting

Hydraulic units and cylinders were fully repaired and all the O-rings were replaced by new ones.

- Corechucks.

The expanding plates were built new ones and fitted for 3 and 6 inches cores.

- De Curling units

Four new de curlers were installed of 10 mm diameter being proper for sensitive paper qualities.

- Slitters

- The shaft of the bottom slitters were renewed (2013)

- Main cutter and Cross cutting section

- Belt section between cross cutter and in feed press was renewed

- Clamps on the knife drums were renewed and coated by felt

- Hydraulic cylinders inside the knives drums were renewed

- Both Hydraulic feeding heads were renewed.

- All electric valves (15 pieces) were changed to new ones)

- The new Smith clutch was assembled as well as the main devices for drive for the upper and lower knife drums.

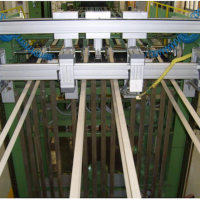

D . Primary belt section and speed control after the cross knives

- The belts have been changed to new ones.

- The short additional belt section was added between the cross cutting and the primary belt sections in order to take the sheets better into the primary belts from the cross cutter.

E . Overlapping section

- The new nep rolls (4) were assembled.

- Stop rollers were changed to new ones with the drive acc. to the speed of the bottom belts.

- Bottom and top belts were change to new ones

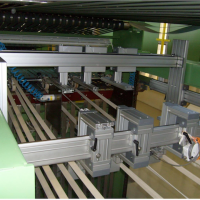

F . Secondary belt section

- The belts were change to new ones

- The sharing gate: in front of the gate the finger lamellas were added in order to

direct the sheets better into the gate. This prevent the jams during the pallet change.

- Delivery section (Lower one)

- The brand 2 pieces of new layboy was built including frame, side plates, new fibrators and back board.

- The nep rolls (4) were changed to new ones

- The top belts were added over for the delivery section 4. Tab inserters (2) changed to new ones

- Delivery section (Upper one)

- The brand new layboy was built including frame, side plates, new fibrators and back board.

- The nep rolls (4) were changed to new ones

- The top belts were added over for the delivery section 4. Tab inserters (2) changed to new ones

- Pallet non-stop change

- The PLC-program was changed to improve counting and auto pallet change using two separate layboys.

Accoding to the above improvements and modernization

1) Productivity was increased from 12 tons to > 20 tons/shift (80 gsm paper)

2) The cutting accuracy was improved to the level of +-0.2 mm

3) Stacking quality was improved being now +-0.2 mm

4) Run ability of the cutter was improved basing much on the automation built through the PLC.

In 2017 the PLC was upgraded to S71200 system, the brake control was upgraded also with IP converters connected to the PLC.