Fourdrinier Type Paper Machine Voith, 3230mm, Fine Paper and Coating Base Paper 51 – 344gsm

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10321

- Name: Fourdrinier Type Paper Machine Voith, 3230mm, Fine Paper and Coating Base Paper 51 - 344gsm

Make : Voith

Last major rebuild : 2005

Working Width : 3230 mm

Capacity : 230 t/24h

Max. Operating Speed : 320 m/min

Paper Grade : Fine Paper and Coating Base Paper

Basis weight range : 51 – 344 g/m²

Raw material : Virgin Pulp Stock Preparation and Approach Flow 2 horizontal bale conveyor belts, incl. drive and controls

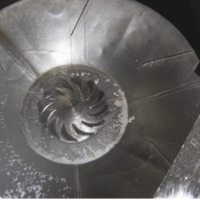

2 Pulpers, make ESCHER-WYSS, volume 35 m³, capacity app. 250 t/24h, with stainl. steel vat

4 double-disc refiners, make VOITH

2 Deflakers, make VOITH

1 4-stage Cleaner Plant, make VOITH

1 Pressure Screen, make VOITH

1 Vibration Screen, make VOITH

1 Broke Handling System incl. couch broke pulper and dry broke pulper and all related equipment of the broke handling system All tanks, chests, pipes, pumps, agitators, valves, measuring and control instruments complete from pulpers to inlet of headbox, incl. all drives and drive controls

Papermachine

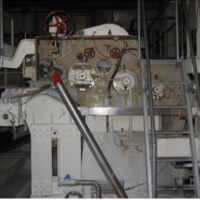

Pressurized headbox, make VOITH, Type G, year of make 1979, with 2 rectifier rolls, tapered Manifold and cross-profile adjusting spindles. Made of stainless steel.

Wire Part, cantilevered, made of stainless steel, year of make 1979, including dandy roll, all dewatering elements with ceramic covers, wire rolls, showers, pneumatic wire guide and electric wire stretcher

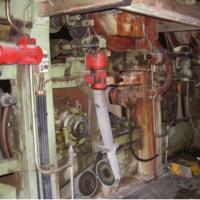

Press Part, year of make 1979, 1st and 2nd nip with central suction press roll 910 mm dia and 2 crown controlled swimming rolls (Kuesters) 425 mm dia with PU-cover, 3rd press with Stonite covered press roll 750 mm and 1 crown controlled swimming roll (Kuesters) 425 mm dia, 4th press with 2 press rolls, rubber covered 750 mm dia,

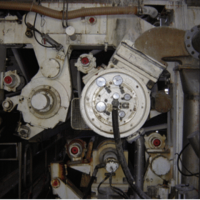

Pre-Dryer part with 30 drying cylinders 1500 mm dia, 3 bars steam pressure, oscillating and stationary doctors, roller bearings with central oil lubrication system, pneumatic felt guides and manual stretchers, pocket ventilation by hot-air blow rolls (Madeleine), with closed hood and ventilation system, make G&H, year of make 1986, with electric operated lifting doors, and including all steam and condensate equipment up from main header steam line

Horizontal type size press, make VOITH, year of make 1969, including starch preparation and starch feeding system

After-Dryer part with 14 drying cylinders 1500 mm dia, 3 bars steam pressure, oscillating and stationary doctors, roller bearings with central oil lubrication system, pneumatic felt guides and manual stretchers, pocket ventilation by hot-air blow rolls (MADELEINE), with closed hood and ventilation system incl. heat recovery system and including all steam and condensate equipment up from main header steam line. 1st dryer after size press is chromium plated

The hood and ventilation system for Pre- and after dryer part is equipped with a high efficient heat recovery system

4-roll machine calander, make ESCHER-WYSS, year of make 1977, with 2 Nipco-swimming rolls, 1 solid steel chilled iron roll and 1 drive roll made of chilled iron including doctors and pneumatic loading and unlading device

Pope reel, hydraulic type, make REINHARD, year of make 1989, including reel spool magazine and automatic empty-spool-starter-system and reel spools

PM-drive for wire and press part as well as Pope reel is equipped with single motors. The rest of the machine is driven by a line-shaft transmission with a 540 kW main motor (SIEMENS). Complete including drive controls, MCC’s, and operation panels.

5 set of reel spool stands The following main spare parts are available:

Various wire and felt rolls for wire and press part

1 spare roll each for each type of press roll

3 spare rolls for size press

1 full set of spre rolls for each roll of machine calander

Various gear boxes and motors.

Wires and felts for each group in total purchase value of € 280.000