Paper Machine 2700mm, Laminate Base Papers, 50-200gsm, 45tpd

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10534

- Name: Paper Machine 2700mm, Laminate Base Papers, 50-200gsm, 45tpd

Papers produced were: pre-impregnated papers, resin load papers, impregnated balancer papers, impregnated backer papers and impregnated paint base papers.

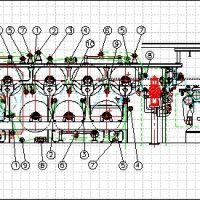

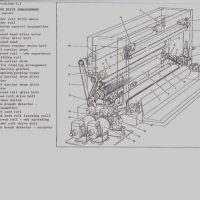

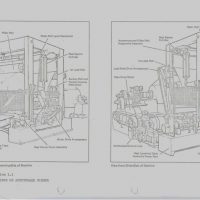

The paper machine has a right hand drive and wire section, two press sections and two lineshaft drive dryer sections. The size press, two after dryer sections, two calendars and reel up are sectional electric drive. Machine speed averaged 110 m/min although the machine is capable of 285 m/min.

Stock preparation

The main pulper is a Lamort stainless steel batch pulper fed from a horizontal conveyor. The pulper is batch with stainless tub and it has a high consistency, recently fitted, rotor from a 9c/mtr. Valmet pulper. Drive is v belt from a vertical motor.

Old standby pulpers are BCI 10ft batch pulpers: one is missing the rotor in the CI sectional tub pulper and the other is m/steel with stainless lining. The pulper has a Volkes standard rotor.

The main refiners are a Jylhavara model JCO-1 refiner and three Pilao Tri disc refiners believed to be of 20” disc diameter.

(There are two further spare refiners, model Pilao Tri Disc 20” with gear motor loading, at the rear of the mill.)

The trim refiner is a Jylhavara model JCO-1.

The stock chests are concrete with various mixers. Consistency control is by BTG NK2000.

There are LD cleaners in three stages with stainless steel tops and polyethylene basis.

The pressure screen is a Beloit model 10, in stainless steel, with perforated baskets.

(Spare body for model 10 pressure screen is at the rear of the mill.)

Paper machine

Wire section:

The flowbox is a pressure flowbox with a multibranch manifold, stainless steel construction.

The slice has an ABB thermo control adjustment from the computer, year 2000, two internal evenor rolls and an internal shower, centres from breast roll to couchres are 10 mtrs, stainless forming board and foil units with polyethylene blades , 5 foil unit before dandy, stainless suction box under the dandy and a suction box after the dandy. There is a manual operated tail cutter and the sheet transfer from the Millspaugh bronze cantilevered suction couch is by an internal air blower. The wire frame is mild steel. There is a Thune automatic wire guide under wire trays and a hog pit including agitator.

The mill has, in store, a stainless steel wire frame cantilevered and an Esher Wyess flowbox which they purchased to rebuild and improve the wet end. The wire frame also includes the wire shake motion and foil units.

The vacuum system comprises three Nash CL2001 vacuum pumps with V belt drives.

Press sections:

The machine has two press sections: both are plain presses, through type with A/F bearings and pneumatic loading.

The first press has a roll with 3225mm face width with centres of 3657mm and a second roll with 3225mm face and 3390mm centres. Thune automatic guides.

The second press has a roll with 3300mm face width, centres of 3657mm and a second roll with 3225mm face and 3657mm centres. Thune automatic guides.

Pre Dryer sections:

All dryers and size press are in a fully enclosed modern Spooner hood with front lifting doors.

The first dryer section with six dryers has slalom felt arrangement, the cylinders have internal bolted ends, centres 3657mm, face width 3500mm and diameter 1500mm, operating 30 psi, open gear drive, central lubrication system, felt rolls on central grease system, Thune auto guides, fixed scoops for condensate.

The second dryer section with six dryers has slalom felt arrangement, the cylinders have internal bolted ends, centres 3657mm, face width 3500mm and diameter 1500mm, operating 30 psi, open gear drive, central lubrication system, felt rolls on central grease system, Thune auto guides, fixed scoops for condensate.

Fibron tail feed system feeding sheet from dryer into rope system for size press.

Scanner cross machine for measuring moisture and profile prior to size press.

Inclined size press, pneumatic loaded with recirculation tank and screen.

There are two non contact air after - dryers and the remaining six dryers have centres 3657mm, face width 3500mm and diameter 1500mm. The dryers have 30 psi working pressure with the exception of two cylinders working at a pressure of 100psi. Thune automatic guides.

Calender stacks:

First calendar: two chilled iron rolls, one Kuster roll with hydraulic bottom loading. Bottom roll heated with independent heating unit.

Second calendar: two soft nips with three rolls. Two rolls are Kuster type. Hydraulic loading from the base.

ABB Cross machine scanner, year 1999, measuring moisture, profile, ash and grammage.

The machine has in line porosity measuring, also has a colour head.

Before reel up is an air transfer through an Ulma cross machine hold detector.

Horizontal track reel up: pneumatic operation with tape transfer and optional Goose neck transfer.

All paper machine control stations are in stainless steel cabinets with LED displays.

The machine has a full width crane at the wet end and two mono rail cranes at the dry end.

The heating unit and chemical size resin make up units are located in an area to the rear of the paper machine.

The machine has spare rolls including spare drying cylinders.

A full machine drawing with roll data is available on request.

Finishing equipment

Sheeter: Strachan and Henshaw simplex sheeter, model 1700, year 1988, speed 200m/min, dead knife operation, maximum knife load 500 gsm, twin roll single Favalessa model PBF shaftless floor pick up unwind, year 1988, 1500mm diameter, variable roll widths to a maximum of approximately 3000mm. Core diameters that can be accommodated are 153mm, 70mm and 76mm. Whichata disc brakes, tension control, three slitters, sheet length 450mm to 1600mm, overlap with tape delivery, to a chain pile lifting layboy.

Possible counter and tabers. SOLD !

Rewinders:

1. Masson Scott rewinder model Autotorque, 2700mm paper width, serial number 7148201, year 1978, speed 1500m/min, drive on the right from the unwind side of the rewinder. Reel shell unwind for 1500mm diameter reels with lateral movement and brake generator 126 kw, two drive motors, 100/150 BHP, 12 slitters fitted with two currently in use, tail tape feed, rewind minimum diameter 70mm and maximum reel diameter 1500mm, driven rider roll x 2 5 BHP, cores minimum 70mm and maximum 150mm, reel ejector and lowering table.

The rewinder dimensions are: height 3250mm and overall weight 26 tonnes.

Eurotherm 590 link drives installed 1996, Mitzibushi A 1S plc, closed loop tension control on the unwind via a CMC load cells and carried out within the 590 link system. (Can also be operated open loop).

Two Eurotherm touch screens contain starting, stopping, various tension and meterage controls, diagnostics, motor running conditions (amps, volts and machine rpm.)

Full specification with motor/generator details are available on a separate document by request.

2. Gordistini rewinder year ----, model---, unwind and rewind diameter---, operating speed ----,

Single shaftless floor pick up for roll diameter----, twin air cooled disc brakes, slitters manual set and number available -----, rewind diameter--- roll ejector and lowering table -----, drive on --- side when looking from the unwind.

Neil to investigate if any photos as erected, drawings and specification on the Gordistini rewinder. Baler:

External baler for sheeter/rewinder trim: Powercrush model 85. The unit has air balance manifold on the inlet to stop trim feed returning to system.

Boiler:

Duel fuel boiler Robey manufacture, year 1986, recent test in 2008, operating at 100 psi, capacity 20,000 lbs/hr, duel fuel burners.