Paper machine 8500mm

-

Print this page

- Product ID: VAK10822

- Name: Paper machine 8500mm

These machines will only be sold for the production of brown grade papers.

Year built: 1974, of Valmet manufacture. Speed1000 m/min, 165,000 t/year, trim 8400mm, gsm 45 to 55. Wire part: Valmet Symformer R, upgraded 1985. Valmet Twinver press with three nips. 52 dryers in four groups. QCS systems: ABB year installed 2010. (Complete new system software and hardware.) Machine computer system: Seimens PCS7 Soleplate centres: Wire section: 9,880mm Press section: 10,050mm Drying sections: 9,950mm Theoretical Production Table:| Speed (m/min) | Grammage (g/m2) | Efficiency | Trim | Production (t/day) |

| 1150 | 45 | 1 | 8400mm | 626 |

| 1130 | 45 | 0,88 | 8350mm | 538 |

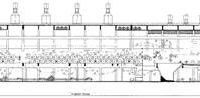

Gear drive system for dryers (pictures) In basement: variable speed fan pump and four CL 9002 T vacuum pumps with a common drive. The mill has two reconditioned CL9002 T pumps spare. Stock and water pumps. Paper Machine Headbox: Symflow 8820mm slice width, profile control by 72 actuators 123m with electrical stepmotors. Thermacontrol of the headbox, slice design speed 1000 m/min. Headbox 1200m/min. Drive is ABB , design speed 1000m/min and DC operation. Instrumentation Seimens teleperm, Mx control system. Maintenance by SKF microlog and ABB Argus systems. Heat recovery by Valmet Pansio. Former: Symformer R with 85 actuators, outer wire width 9100mm wire length 24,300 m, inner wire width 9100mm and length 50,000 mm. Installed power 1.620 Kw. Two suction boxes and vacu foils. Wire is cantilevered with stainless frame. Press section Suction pick up. Press type Twinver and third press. Felt length 30,000 mm: first nip loading 70Kn/m. Felt length 25,500 mm: second nip loading 90 kN/m. Kuster roll installed Felt length 26,000mm: third nip loading 90 kN/m. Kuster roll installed Ule felt cleaning box. Steambox in press section with 117 actuators. Fourth nip loading to be specified. Valmet steam box with 40 zones. Dryer Sections 52 Drying cylinders in four groups, 1500 mm diameter, A/F dryer bearings with auto lub system. Operating pressure of drying cylinders is 2.5 bar. Oil tank in basement. System has a centrifuge for water separation from oil. Totally enclosed dryer hood with front lifting door, sheathen rope tape tail feed. Sectional electric drive. Dryers have enclosed gear drives. Dryer sections one and two are the main steam groups, with single felt. Third and fourth dryer sections are cascade system. Dryer felts are 48,000, 107,000, 66,500 and 43,000 mm lengths. Felt cleaning by nozzles and chemically cleaned in during machine shuts. Moisturiser between third and fourth group with 117 actuators (VIB dampening systemoperated by air pressure and water.) Runability systems: uno run, sym run and press run. Reel Up Valmet horizontal reel up with roll accelerator, hydraulic operation, maximum roll diameter 2600mm, maximum roll width 8500mm. Grooved drum, reel shell diameter 770 mm. Ulma hole detector. General:(VAK 10821 & VAK 10822)

The paper machines have a range of spare wires and felts. Each paper machine will be sold with one overhead crane. There is a full photo data base showing the system through each paper machine. Foundation, plan and side elevation drawings are available on the paper machines.