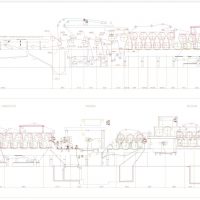

Paper Machine Beloit Walmsley 4400mm, 48-70gsm and On Line Coater

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10347

- Name: Paper Machine Beloit Walmsley 4400mm, 48-70gsm and On Line Coater

* Maximum Speed: 800mpm (2624 fpm), avg. 2005: 758mpm(2486fpm). * Wire Width: 5.02m (198 in). At the winder, maximum width is 4.40m (173 in).

* LWC offset product between 48 to 70gsm (32.4 to 47.3Ibs). Avg. 2005 was 67gsm (45.2Ibs). Matt paper produce on Supercalenders (1 nip).

* Daily average production of 263 mtons in 2005, 90.000tpy

Wet end section

* Beloit Fourdrinier (1956) with a dilution headbox from Beloit(Concept IV MH 1994) control by the Measurex QCS system (OPEN)

Press section

* The 4-nip Beloit press section (1985, 4th Allimand in 1986) has a straight through 1st press and a 2nd nip between a top granit roll (new ceramic purchased) and a bottom vacuum roll from Beloit.

* The 3rd and 4th press are separate with a top granit roll (Ceramic Valrokfrom Valmet in 3rd position, 1996) and a bottom pressure roll (4th : Sym roll fromValmet).

Dryer section

* 47 cylinders from diameter 1 m 50 (59 in). Conventional dryer from 1956.

* One Unirun at the beginning. 5 mechanical section with drives.

* New steam and condensate system (May 2000) with fix siphons from Johnson.

Hard nip calender

* 2 full steel rolls with a Caltrol system to adjust final weight at the reeler.

ON LINE COATER

Coating heads

* 2 Short Dwell from Beloit (1983). No profiling system.

Coater dryer section

* Hot air system: 1 Overly in 1st coater, 1 Air cap on the 2nd coater.

* 6 drying cylinders diam 1m 50 (59 in) in first coater.

* 7 drying cylinders diam 1m 50 (59 in) in second coater.

PM reeler

* Conventional with primary, secondary arms (pneumatic) from Beloit (1966).

* Maximum diameter 2m 20 (87 in) means one set of 1m 25 (49 in) ortwo sets of 1m (39 in).

Others

* Measurex Open QCS and DCS System.

* ABB Ulma 3 D Holes detector.

* SPH 19 Headbox screen from Lamort (reused from PM 1).

* Lamort broke screening (holes first, slots after).

* Old drive conception on the PM dryer: 2 big motors with 2 line shafts and belts drive system to the dryer section. In may 2000, we have replaced these old drive system on coater by new AC drive from ABB.

FINISHING PM 3

Releerer

* Beloit with conventional pope reel and secondary arms (pneumatic).

* Maximum speed 2300 mpm (7550 fpm).

Supercalenders

* Two 12 rolls ECK Supercalenders (Open Frame design) from 1957 and 1964.

* Speed 600m/mn (1970 fpm).

* Type of pressure rolls: full steel rolls with fix crown. No rapid drop inbottom nip.

* Type of Thermo rolls: with central hole (design for steam heated) heated by hot water 120 °C (250 Fahrenheit). New heating unit from 2000 (May, AURA Company).

* Polymer: 2 per Supercalender (6 in total, STOWE cover on cotton).

* Wind up system: conventional pope roll system with secondary arms(hydraulic).

WINDER and WRAPPER

* One JR1000 winder(1991),maximum speed 2300mpm (7500 fpm). 6 tons max (2 “postes lourds”), the others being 4 tons. Usual max diameter is 130 – Max width 3,60 m. Technical max specs being 1,50 m.

* Elevator: 3 tons max. Check hydraulics. Max width is 3,00m. (SERMAN)

* “Cuiller” to vRoll 3 tons max.

* Trays of conveyor belt vRoll, no problem up to 2 m width, 1,28 diameter, so roughly 3,2 tons (LWC). Above, physically working but load and efficiency of the equipment will be challenged. Wrapping : diameter max is 1,28 m. Max width is 3,00 m. Hydraulics is OK.

General Info

Supplier :Beloit Walmsley

Start-up :1932

Rebuild history :1956 speed up to 600m/mn :1985 speed up to 800m/mn new press section :1986 new dryer frame, improve coater sheet run. :1990 new winder. :1994 new headbox. :1999 Upgrade SC, new drive on coaterand steam/condensat system onPM dryerGrade(s) LWC offset,48 - 70gsm Designspeed 800m/min Max. trim width 4,40m

Headbox

* Type Concept IV-MH slice pcs. * Use only manually for TSO adjustemer profile control Dilution

Former

* Type: Fourdrinier from 1956 (BELOIT)

* outer wire width NA

* outer wire length NA

* inner wire width 5m

* inner wire length 45m 43

* installed driving power Couch 191kW, Turning Roll 280kW

* suction boxes 7 pcs

* vacu-foil boxes 0 pcs

Press section

* Type Straight through 1st and 2nd press (common and so call transfer felt), separate 3rd and 4th press

1.Nip

* Loading 60kN/m

* Felt length 30m

* Uhle box pcs.2

2.Nip

* Loading 60kN/m

* Felt length 20m 50

* Uhle box 1 pcs

3.Nip

* Loading 80kN/m

* Felt length 16m 40

* Uhle box 1 pcs

4.Nip

* Loading 90kN/m

* Felt length 17m 70

* Uhle box 1 pcs

| Felt cleaning Standard and old fashion HP showers |

| Felt cleaning during shut downs Choc cleaning with NALCO |

|

Central roll cover Valrok and CeraLease on 3rd press top, rest gran |

|

Suction roll cover No central suction roll in this kind of press steam box No |

Drying section

* Drive groups pcs. 5

* Steam groups pcs. 4

* Single fabric 1

* Cylinder pcs. 47 (6 not heated)

* Fabrics 9

* Fabric cleaning Nothing

* Threading system Ropes

* Runability system No blow boxes

Coating

Number of coating stations :2 type SDTA from BELOIT (1983)

Supplier :Beloit

Mode of operation :on

Type :blade SDTA

Started :1983

Speed :800 m/min

Range of coat weight :8 to 12gr/m²

* Control system Caltrol on machine calender to adjust final weigth at the re

Calander

| Number of calanders | 2 |

| Type | Supercalander |

| Supplier | Eck |

| Started | 1957 / 64 |

| Mode of operation | off |

| Speed | 600m/min |

| Control system | Nothing |

| Max. loading | 300kN/m |

| Max. surface temperature | 70°C (inside thermo roll hot water 120°C) |

| Rolls | 12 (4 Thermo rolls, 2 polymers, 4 cottons) |

| Caliper profiling | Nothing (no control system) |

| Zones pcs. | No zones: just king rolls on top/bottom nip |

| Roll covers | Polymers on cotton directly by STOWE |

* Type Conventional primary and secondary arms (pneumatic) from BELOIT

* Max. reel diameter 2m 20

* Max. reel width 4m 55

* Loading system Pneumatic cylinders

* Cylinder coating Carbide cover

* Grooving Groove

* Spool diameter 420mm

Winders

* Type Valmet JR 1000 (center)

* Installed 1990

* Speed 2300m/min

* Roll width range 440-2000mm

* Max. roll weight Design up to 6 tons (heavy station, normal 4 tons)

* Max. roll diameter 1250mm

* Slitters pcs. 10

* Drive BBC (revamping from previous 2 drum winder)

Rewinder

* Type Jagenberg Vari Rol

* Installed 1986

* Speed 1500m/min

* Max. roll width Limited to 2m due to Von Roll Conveyor to Wrapping line

* Max. roll diameter 1m 25

* Slitters pcs. 3

Line Drive

* Type ABB on 4th press and coater (1999), rest BBC (1956)

* Supplier ABB, BBC

* Max. speed 800m/mn

* Control system MEASUREX Open

Automation

* Instrumentation MEASUREX Open

* Quality control MEASUREX Open

* Maintenance

* Fault detector ULMA before PM ree

Heat recovery

* Type, supplier Mainly Brunschweiler and Belo

Vacuum system

* Type, supplier Water rings pumps