Paper Machine Fourdrinier 3200mm, 40-120 gsm, 140 tpd

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10396

- Name: Paper Machine Fourdrinier 3200mm, 40-120 gsm, 140 tpd

Fourdrinier PM ANDRITZ - ESCHER WYSS

Built: 1960

Rebuilt: 1984

Last production 2000

Product range: Writing and printing woodfree paper, one- and bothside coated paper

Basis weight: 40-120 g/m2

Trim width: 320 cm

Speed: 400 m/min

Construction speed: 500 m/min

Capacity: 140 t/day

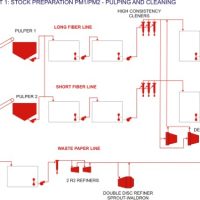

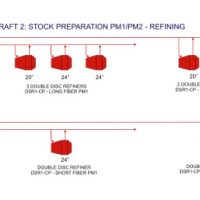

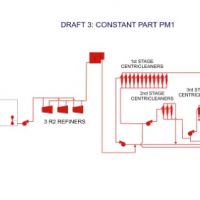

STOCK PREPARATION STILL AVAILABLE!! Complete stock preparation line for PM1&2 with equipment shown and additional equipment for preparation and dosing of different aids and fillers, complete with regulation and control.

All equipment from headbox to pope roller including:

All equipment from headbox to pope roller including:

1. CONSTANT PART – FLOW APPROACH SYSTEM (with equipment shown)

2. HEADBOX – Step diffuser

2. HEADBOX – Step diffuser

3. WIRE SECTION

4. PRESS-SECTION

3. WIRE SECTION

4. PRESS-SECTION

Three-nip press-section consisting of:

- 1st nip: suction press 45 N/mm

- 2nd nip: Nipco-press with line pressure cross regulation – 70 N/mm

- 3rd nip: Simple press with bottom grooved PU roll – 100 N/mm

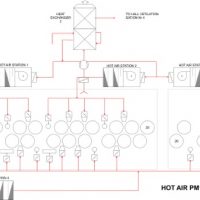

5. DRYER SECTION SEPARATED IN TWO SECTIONS

5. DRYER SECTION SEPARATED IN TWO SECTIONS

(shown below):

- Preliminary dryer section with 24 drying cylinders (∅1500 mm) separated in 5 dryer groups

- Second dryer section with 10 drying and 2 cooling cylinders

- Heat exchange with 2 heat exchangers

- Hot air facility with 4 hot air stations and 20 blowers in dryer sections (10 blowers with cross regulation and 10 simple blowers)

6. DIFFERENTIAL COATING DEVICE BILLBLADE

6. DIFFERENTIAL COATING DEVICE BILLBLADE

Built: 1984

In operation: 5 years

Device with 3 rolls and blade holder, with 3 modes of operation:

- Size-press

- One-side pigment coating 10 g/m2 (oposite side – starch)

- Both-side pigment coating (10 + 10 g/m2)

7. COATING KITCHEN SOLD!!

7. COATING KITCHEN SOLD!!

Supplyer: GAW

Built: 1984

In operation: 5 years

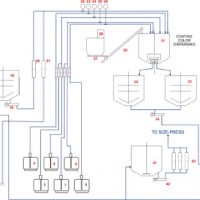

The coating kitchen consists of the following eqipment (shown on the draft):

- 2 tanks (25000 l each) for synthetic binder (fiber-glass plastic)

- 6 container dosing screw pumps

- Starch cooker 2000 l with mixer

- 2 tanks for sarch, 5000 l each, with mixers

- Autoamtic scale for pigments (2000 kg)

- Dispersing machine Kady Mill Type 500B

- 2 tanks for coating color, 10000 l each, with mixers

- Working tank for starch (800 l) with mixer and pressure filter

- Working tank for coating color (800 l) with mixer and pressure filter

- Programmable automatic operation

- Screw pumps for liquid transport

- Complete measurement and regulation

8. MACHINE CALENDER

8. MACHINE CALENDER

Built: 1984

In operation: 5 godina

Two-roll Nipco calender

Bottom roll: ∅560 x 3600 Nipco roll (hardness 500-520ºHB)

Top roll: ∅600 x 3600 (hardness 500-520ºHB)

Line pressure: 120 N/mm

9. PROCESS CONTROL SYSTEM

9. PROCESS CONTROL SYSTEM

Model: Accuray 1180M

Two measuring frames for basis weight and moisture measurement:

- U-frame before coating device

- O-frame before machine calender

Measurement and control of basis weight and moisture.

Calculation of coating weight.

Calculation of ash content.

10. POPE ROLLER

Paper machine 1 including coating kitchen has been sold, Stock preparation STILL AVAILABLE!

10. POPE ROLLER

Paper machine 1 including coating kitchen has been sold, Stock preparation STILL AVAILABLE!