Paper Machine Smith Anderson Deckle 2400-2640mm 34-100gsm, 90 tpd

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10345

- Name: Paper Machine Smith Anderson Deckle 2400-2640mm 34-100gsm, 90 tpd

Type Machine Glaze (MG)

Deckle 2400-2640mm

Substanse Range 34-100gsm

Reeler type Jagenberg

Full Deckle 2680mm

Deckle Trim 2640mm

Minimum Diameter 640mm

Maximum Diameter 1400mm

Minimum Centres 70mm

Masimum Centres 203mm

Minimum Reel Width 155mm

Maximum Number of Webs Across Machine: 17

Stock preparation

5E Lamort H.C. pulper, volume 20 m³, in stainless steel, with 14ft diameter tub. Poire model two stainless steel reject screen. Gearbox drive to a helical rotor.

Fed from a waste paper inclined ELCO two meter wide conveyor.

Krima C line for production of 120t/day, year of manufacture 2000. Three inclined screw presses, horizontal screw, fluffer feed screw, heated horizontal screw and Krima KD 710 disperser.

This unit has had a replacement shaft with bearings and a new set of fillings fitted prior to the mill closure.

Four Comer Spider de inking cells, stainless steel each with Ahlstrom feed pumps. Year of manufacture 2000. Production is 3 t/hr.

Two Lamort H.D cleaners with auto dump valves and timers.

Black Clawson Ultra screen model 2.

Finckh horizontal screen model OE HS with 2mm holes. Year is 1996.

Rejects to Finckh v/screen.

Delta screen and mini Delta with 0.15mm slots.

Rejects to Fan separator.

Fibre recovery by Kufferath disc thickener.

Refiner is a Pilao 24” disc refiner Tri-Disc.

Trim refiner is a Pilao 20”.

Approach flow:

BCI, L.D. 14” cleaner followed by Celleco three off model 410 cleaner and a further two of model 206 cleaners. The Celleco cleaners have ceramic cones and fibre savers on the 206 cleaners. Beloit pressure screen with stainless steel body. Drive is by V rope.

Pressure screen rejects to a Finckh model E1.5 with 2mm holes. Vibrating screen with stainless steel body and C.I. rubber lined base.

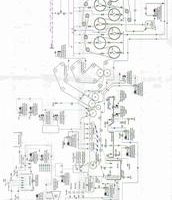

Paper machine

This is an M.G machine with a drive on R/H from the flowbox, producing envelope and bag papers from recycled fibre. Manufacturing for world leading companies, deckle is 2700mm, speed 160 to 600 m/min, production is 3.8 ton/hr, 34 to 100 gsm. Original year of manufacture was 1970. Many new parts installed in 1982 with the only original parts being the after-dryers. The M.G cylinder was installed in 1982.

Wire part

Overhead crane, stainless wire frame cantilevered design. Removable packers to enable wire changes. Frame centres are 3400mm. breast roll to couch centres 15m, approximate wire length is 27.6m to 28m. Overmeccanica pressure operating flowbox, 2900mm slice width, steel body with stainless steel lining, internal shower, two driven holey rolls, multi branch manifold with MX profile optimiser computer adjusted slice control, 21 motorised slice adjusters. Reiss breast roll 590mm diameter. Johnson stainless forming suction board. Ten stainless foil units, two of the foil units having fan assisted operation. Four suction boxes. All covers are plastic. Thune tail cutter. Overmeccanica suction couch on A/F bearings and bronze shell, 720 mm diameter approximately and cantilever design. Wire guide is of Thune manufacture.

Devroniser steam shower profiling unit over suction couch.

(Asset subject to finance)

Air sheet transfer.

Wire pit extends below presses and has vertical agitation.

Press sections

Overmeccanica press sections with suction pick up roll, the first press being a combination press, double felted, top roll 560mm diameter and face 3100mm, max pressure 382 pli, centres are 3780m, suction roll approx 600mm diameter. The second press is a blind drilled press, top roll 1000mm diameter face 3050mm , load is 100 pli. Both presses are pneumatic loading. All rolls are on A/F bearings.

Drying sections

Seven pre-dryers Westbury manufacture, A/F bearings, diameter 1500mm, face 2960mm, operating pressure is 90 psi. This section was rebuilt in 1982. Bolted ends, frame centres are 3560mm, sheathen rope rings, open gear drives with C.I. and Poly Pemco segmented gearing. Auto central lub system. Thune automatic felt guides model 125/170-80. Tail is by sheathen rope feed. Operating pressure 33 psi.

M.G. cylinder Beloit manufacture, year 1982 , cylinder 6000mm diameter, face 3080mm, centres 3990mm, bolts on cylinder ends are 210mm centres, sheathen rope ring in cylinder face, A/F bearings, single press roll on A/F bearing and pneumatic loading, operating pressure 68 psi. Brunnscweiler gas fired hood steam and condensate system. The cylinder is turned weekly to avoid flats on cylinder bearings and to keep the diameter true.

After-dryers are Westbury drying cylinders as pre-dryers with an operating pressure 45 psi , thermo compressor and sheathen rope feed.

Honeywell scanner model 4000- 20 controlling moisture profiles and gsm. Computer is MX open control 2002.

Horizontal reel up is of Bertrams manufacture rebuilt 1982 with a hydraulic drive producing roll diameters of 1500mm, drum face 2850mm. 5 reel shells located next to reel up.

Machine drive is a sectional electric drive to reel up, after dryers, M.G.

Pre dryers, second press, first press and forward drive roll. Cortina D.C drive suite. Mawdlsey drive motor, ASEA wet end drive motors. Gearboxes are Santasalo manufacture.

Broke pulper is a Solvo manufacture unit 2300mm diameter with a bottom mounted rotor. 2300mm diameter and the body is stainless.

Vacuum pumps

Nash CL2001

Nash CL2001

Nash CL2001

Nash 904 R2

Drysdale 2 VA

Most pumps are Ahlstrom manufacture installed 1982.

Rewinder

Jagenberg Vari-Dur two drum rewinder, R/H drive, model 33015/500 AB 2800, working width 2800mm, year 1978, number 3022856, shaft unwind for paper machine shells, water cooled drum brake with three sets of brake shoes, lateral roll movement, auto tail feed, camber segmented roll, tension control, shaft-less rewind, reel ejector and lowering table, roll diameters are 1500mm, 13 air slit slitters, single motor drive 127 kw, 1800 rpm, 400v, 50 cycles and 3 phase, design speed 1800 m/min. running 70, 76, 102 and 150mm cores.

Floor mounted reel scale with LED read out.

Trim fan/shredder feeding to a Handley horizontal baler with feed hopper.

Overhead crane for reel movement and paper machine repairs rated at 5 ton capacity.