Paper Machine Smith Anderson Deckle 3400mm-3660mm 44-150gms, 90tpd

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10346

- Name: Paper Machine Smith Anderson Deckle 3400mm-3660mm 44-150gms, 90tpd

Type : Machine Glaze (MG)

Deckle : 3400-3660mm

Sustance Range : 44-150gms

Reeler Type : Pasaban

Full Deckle : 3700mm

Deckle Trim : 3660mm

Minimum Diameter : 440mm

Maximum Diameter : 1400mm

Minimum Centres : 70mm

Maximum Centres : 203mm

Minimum Reel Width : 168mm

Maximum Number of Webs Across Machine : 21

Minimum Width of Side Run Coils : 147

This is an M.G machine with L/H drive from the flowbox, producing envelope and bag papers for world leading companies, deckle is 3700mm, major rebuild in 1987 with new M.G., speed 150 to 400 m/min, 40 to 180 gsm, producing 3.8 t/hr. Only original parts are pre dryers 1970 man.

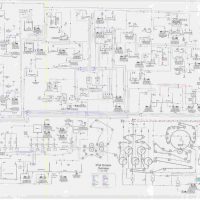

Stock preparation

Two Lamort H.D. cleaners with timed reject and automatic valves.

Black Clawson Ultra screens model 1 and 2 in stainless,baskets 2mm holes.

Rejects to a vibrating screen

Two Delta screens and mini Delta with 0.15mm slotted baskets.

Rejects to a Fan separator.

Back water fibre recovery by Kufferath disc thickeners.

Claflin model 202 refiner.

Pilao 20” disc refiner

Approach Flow

BCI 14” L.D. cleaner, three Celleco model 410 and two model 206 with ceramic cones, Bird pressure screen with rejects to a Finckh E2-1.5 vibrating screen.

Wire Part

Voith flowbox pressure operation, steel body with stainless lining. Designed for max flow of 7 t/hr, multi branch manifold, slice 3940mm, frame centres 4430mm, two driven holey rolls and driven internal shower, 30 off micro adjusters for moving slice lip, centres from breast roll to couch are 13m. approximately. Bertrams shake motion, stainless cantilevered wire frame

with removable packers to assist in wire changes, edge deckles at slice outlet, forming board, ten Johnson foils stainless steel, five suction boxes, all tops plastic covered, Millspaugh suction couch with bronze shell, A/F bearings, cantilevered type, 910mm diameter approximately

Overhead crane for roll changes etc.

Devroniser steam shower profiling unit over suction couch.

(Asset subject to finance)

Press sections

First press section is a Millspaugh suction roll on bottom with granite top roll, second is a plain press with micro rock and micro mate covers. All bearings are A/F and rolls have pneumatic loading, roll face 4150mm and centres 4450mm.

Drying sections

Five pre dryers Westbury manufacture, internal bolted ends, 1500mm diameter, A/F bearings, open gear drives with C.I. and Poly Pemco segmented gears.Operating 34 psi.

MG cylinder, Walmsley diameter 5000mm, face 4140mm, A/F bearings, 4600mm centres, year 1987, operating pressure 55 psi. Brunnscweiler gas fired hood steam and condensate system. The cylinder is turned weekly to avoid flats on cylinder bearings and to keep the diameter true.

Three after dryers 1500mm diameter. Westbury manufacture with A/F bearings, open C.I. and Poly Pemco segmented gearing. Operating pressure 15.5 psi.

Measurex scanner contRolling profile moisture and grammage.

Horizontal reel up pneumatic loading for roll diameters of 1500mm. Complete with five reel shells.

The machine has a sectional electric drive to reel up, after dryers, M.G., predryers, second and first press, forward drive roll on the wire.

Vacuum pumps:

Nash 2002

Nash 2002

Drysdale 5VA

Rewinder

Passaban two drum rewinder , model KD 1700, year 1995, width 3750mm, design similar to a Jagenberg Vari-Step, max reel width 3900mm, shaft unwind for 1500mm diameter with water cooled brake, five sets of air operated brake shoes, stand has lateral movement and pneumatic clamp to lock reel shell when rewinder is in use, 19 slitters, auto tail feed, auto tension control, camber roll, twin motor drives, Onemon manufacture, shaftless rewind currently running 70 to 180mm diameter cores, inclined winder drum design with two winder drums of different diameters 500 and 750mm, reel ejector and lowering table. Design speed 2000 m/min.

Toledo floor mounted scales with digital read out.

Trim fan feeding into a Hanley horizontal baler.

Overhead dry end machine house crane for dryer, roll removal also roll loader onto the rewinder.

Two stainless Parkwood endless rotating drain screens complete with waste conveyors

Includes spare wire felts etc.