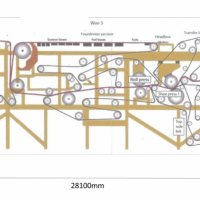

Laboratory / Pilot size paper machine 340mm (headbox) 60-140gsm

-

Print this page

- Product ID: VAK11336

- Name: Laboratory / Pilot size paper machine 340mm (headbox) 60-140gsm

Basic information

Built year: 1982

Press section rebuilt to sym-belt 1996 Andritz head box 2008

Andritz topformer 2012

Weight: approximately 250 ton

Power consumption during normal run: approx 1,5MW

Speed max 2500m/min (design speed), roll-up of wet web after press approx 1000m/min

Width and production:

Andritz headbox 340mm, Valmet headbox 330mm

Cut web through press max 250mm

Production , max 22kg/min (dry weight in headbox)

Example of products manufactured:

Kraftliner 65g/m2 1000m/min, twin wire former

Two ply 140 + 40 g/m2 400m/min fourdrinier + twin wire former Stratified forming on fourdrinier + topformer 85 g/m2 700m/min

History

Built: 1982 by KMV (later Valmet)

updated and rebuilt 1987, in 1996 the press section was totally re-built with two new shoe press nips. A new felt loop for one of the shoe nips was installed 2000.

In Addition to that a new head box and a hybrid former was provided by Andritz in 2009

Forming section

Gap former (STFI former) and Fourdrinier can be run separately or together Outlet width Andritz headbox 340mm, Valmet headbox 330mm

Possibility to mount topformer on Fourdrinier for increased dewatering capacity.

Power consumption during normal run: approx 1,5MW

Speed max 2500m/min (design speed), roll-up of wet web after press approx 1000m/min

Stopped 2024, standing as is in production

Press section

1st press: Double felted roll nip, max press load 150 kN/m

2nd press: Sym-belt lower roll, solid upper countershaft, double felted or single felt with transbelt, max press load 1200kN/m

3rd press: Sym-belt upper roll solid lower countershaft, single felt against solid countershaft, max press load 1200kN/m

2nd and 3rd press have tiltable shoes

Cut web through press max 250mm

Production , max 22kg/min (dry weight in headbox)

Example of products manufactured:

Kraftliner 65g/m2 1000m/min, twin wire former

Two ply 140 + 40 g/m2 400m/min fourdrinier + twin wire former Stratified forming on fourdrinier + topformer 85 g/m2 700m/min

Closed white water system with fiber recovery over Voith disc filter (built year 2007)

Details on production.

large-scale pilot plant that simulates industrial production of paper. In standard configuration there are a twin wire former and a fourdrinier former that can be run simultaneously or separate. There are possibilities to add a second twin wire former. The press section consists of a roll nip followed by two shoe nips. The paper is the winded with a dry content of roughly 40 to 50% and dried of-line. One of the main features are the closed long circulation. Fiber material is re-cycled using a disc filter provided by voith giving the pilot plant a much more realistic dynamic and paper chemicals and additives can be evaluated in an accurate way. All short- and long circulation volumes have been minimized to be able to reach equilibrium as fast as possible.

More details upon request!