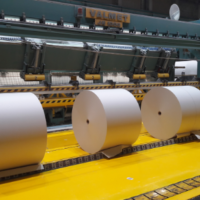

Valmet paper machine Trimmed witdth 8,4 m

-

Print this page

- Product ID: VAK11231

- Name: Valmet paper machine Trimmed witdth 8,4 m

Line basic information

- Start- up 1989 Valmet

- Rebuild 2005 (Voith), 2009, 2010 (Valmet, Voith)

- Product Newsprint and improved Newsprint

- Production capacity 270 000 tons/year

- Basis weight range 34 – 55 g/m2

- Trimmed witdth 8,4 m

- Speed 1600 m/min

- Two Valmet JR-1000 winders

- Rewinder Quattroll 2,6 m

- Automatic packing line, rebuild 2005 (Saimatec)

- Raw materials TMP, RCP

- Headbox Valmet SymFlo HS with dilution profiling (2009)

- Wire section Valmet SpeedFormer HS (vertical)

- Press section Valmet SymPress II with 4th press

- Drying section Valmet SymDry, rebuild Voith 2005, 2010

–6 single tier drying groups, 1 double tier drying groups, 4 drive groups

–Ropeless tail threading, Valmet, Runtech

- Machine calender, one nip with two SymRolls

- Pope reel (hard), max speed 1630 m/min

- Paper width at reel 8,5 m, trimmed width at winders 8,4 m

- DCS Honeywell TP Alcont 2002

- QCS Honeywell Experion 2017,and WIS ABB 2001 (Not included in the sales scope)

–Steambox Devron, Caliber Calcoil, Basis weigth Valmet dilution, Web break monitoring Procemex

Short circulation

- Pumps: Ahlström

- Deculator: Ahlström Ensovac

- Cleaner: Ahlström Twincleaner

–6 stages

–Vacuum system, 2 Nash pumps

- Dilution water deaeration tank: Valmet OptiAir Vac 2009

- Machine screen: Valmet/Metso MS-1200HT, slot 0,25 mm

- Reject screen: Valmet/Metso FS-200VA, slot 0,2 mm

- Dilution water screen: Valmet/Metso Optiscreen MS-50VT, hole 1,4 mm

Water circulation

- Disc filters: Ahlström IKS 45-24.5, 2 pcs

- Super clear filtrate: Valmet ProFS-90LC

Broke system

- Broke thickener: Ahlström PRS 2070.6

- Broke screening: 4 stages (with coarse screen 5 mm)

–Valmet MuST302E, slot 0,2 mm

–Valmet MuST82, slot 0,15 mm

Wire section

- Headbox: Valmet SymFlo HS

–Retrodilution, Valmet 2009, 150 actuators

–Flow width 8940 mm

–Consistency / CD profiling

- Wire: Valmet Speed-Former HS

–Max speed 1550 m/min

–Grooved forming roll without shrink sleave

–1st suction roll

–Curved multifoil shoe, SiC

–2 flat suction boxes, SiC

–HiVac suction box, SiC

–5 Nash vacuum pumps

Press section

- Valmet SymPress II with 4th press

–Pick Up roll, steel

–1st SymRoll, carbide coated

–Center roll, Valmet PressJade

–Press suction roll, PressFox

–3st SymZSRoll

–4th press center roll, Valmet PressJade/Voith CeraLease

–4th SymZSRoll

– 5 vacuum pumps, 3 vacuum boxes (pick-up and 1st press felts)

Drying section

- Valmet SymRun, rebuild 2005 and 2010 by Voith

- 7 drying groups, 4 drive groups

–53 cylinders, 31 heated

- Groups 1-4 original Valmet Single run

–Vac rolls

–UnoRun

- Groups 5-6 Voith DuoStabilizer Single run

- Group 7 Voith Twin run with ropeless tail threading

Calender

- Machine calender, one nip

–Bottom, SymRoll

–Top, SymRoll

- FoilForce tail threading

- Calcoil, profiling

Reeler

- Conventional Pope

- Max reel dia 2,8 m

- Tail threading: FoilForce (Valmet)

- Goose neck

- Water turn up device (Valmet)

Vacuum system, pulpers

- Vacuum pumps Ahlström

–904-T1, 2 pcs

–904-T2, 2 pcs

–904-S2, 3 pcs

–904-R2, 4 pcs

- Pulpers

–Couch pit

–Press Pulper 1

–Press Pulper 2

–Machine Pulper

–Winder pulpers, 3pcs

Automation, paper machine

- DCS

–Honeywell, Alcont TotalPlant, 2002

- QCS (not included in the sales scope)

–Honeywell, 2018

–Profiling, Basis weight (IQDilution), moisture (Devronizer), caliber (Calcoil)

- WIS

–ABB, ULMA, 2001

- WMS

–Procemex, 2017

- Drives

–ABB, DC, Selma

- Machine logic, Siemens S5, some part S7

Winders

- Valmet JR-1000, 2 pcs

–Single drum winders

–Automatic set change (Valmet 2005/2010)

–Core 76/15

–Max reel dia 1270 mm

–Max reel width 2500 mm

–10 stations, 14 slitters

Core cutter

- CoreLink CL 4000/8432

- 4 core storages

- 10 core carriages

Other

- Crane 1, 75 tons, KoneCranes

- Crane 2, 90 tons, KoneCranes

- Crane 3, 15 tons, KoneCranes