VOITH Paper machine 4160mm 36-70 GSM 300 TPD

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK11160

- Name: VOITH Paper machine 4160mm 36-70 GSM 300 TPD

Manufacturer: VOITH

Drive: right hand

Working width: 4160mm

Year of construction: 1986

Main rebuilt: 1998 (rebuilt by Valmet / Metso)

Production speed: 1200 mpm

Construction speed: 200mpm – 1350mpm

Grammage range produced: 36 – 70 gsm

Capacity: 102500 tpy (max 300 tpd)

Paper grades: news print paper produced, furnish waste paper DIP + ground wood

Drive Power installed: 1,8MW

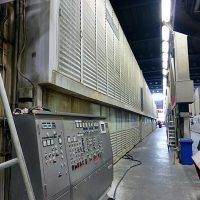

MCC power installed: 3,4MW

Steam consumption: 1,4 to/to

Stock preparation

Total installed power 3,7MW

Sulzer Conveyor belt 1500mm x 38m

Sulzer Pulper ST11CEW 700kW

Sulzer Fiberizer F3T 55kW

HC Cleaner Voith HCC400/15

HC Screening Plant 4 steps with VOITH Spectroscreen 23, 13W, Rejectsorter RS2B and Minisorter

Sulzer Flotation Cells and Microflotation Deltapurge

Voith Sulzer Dispersion Unit complete with Screw Press, Steam Mixing Tube and Disc Disperger

Approach flow system

Machine and Mixing Chest each 140m3

1st Deculator Pump 53000lpm

Deculator Clark Vicario with LD Cleaner Plant Voith KS160/61RC in 4 steps: 84/24/13/3

Fan pump 52000 lpm

1st step 2 items Voith VS21 Pressure Screen with Multifoilrotor Ø1,8mm hole basket

2nd step 1 item Voith VS21 Pressure Screen with Multifoilrotor Ø1,8mm hole basket

Disc Filter for Fiber Recovery from white water 1, Voith Sz II 20/20, Ø 3800mm, 20000 lpm

Rückstoffsortierer Valmet Mu ST202E (3-step pressure screen)

Paper machine

Head box:

Voith Model W with 2 high turbolance rectifier, made 1986, width = 4470mm

Wire part:

Voith Duoformer

Top Wire 4650mm x 14650mm

Bottom Wire 4680mm x 25250mm

Breast Roll

Forming Roll: Ø 1150mm x 4850mm, plastic wire cover

Suction Roll: Ø 1000mm x 4860mm, s/s

Pick-up Roll: 650mm x 4860mm, cover KCR 110 Duplex

Press part:

Duocentri Press, combined to a 3 – nip press

Double Suction Press Roll: Ø 1040mm x 4720mm, Crowning, 3RE60 SolarFlow Cover, grooved 2,3mm, 11 PT P&J

Bottom Groved Roll: Ø 700mm x 4500mm, Cover AquaPress, hardness 5 +/-2 P&J

Central Press Roll: Ø1100mm x 4500mm, Storok Cover ceramic

Sym Roll: Ø735mm x 4500mm, Cover SolarPress, hardness 4 Pt P&J

line pressure: 1st Nip: 70 kN/m

2nd Nip: 80 – 90 kN/m (operating 87 kN/m)

3rd Nip: 95 – 120 kN/m (operating 116 kN/m)

Steam Blow Box

Transfer Foil Roll after Central Press Roll installed

Dryer group:

total number of dryers: 53

5 no of dryer groups

Dryer dimensions: 1492mm x 4410mm + 120mm feeding rope grove

16 items Duostabilzer for smooth web transport

Operating pressure: 2,1 – 2,2bar, 3 bar maximum

All dryers with roller bearings

Calender:

1 – nip Soft Calender without heating

Bottom Roll: Ø540mm x 4300mm cover soft Genesis, Küsters S-Roll

Top Roll: steel Ø780mm x 4300mm

CalCoil Sectional Heating System, 58 zones each 4,6kW

Moinstening System:by VIB

Honeywell QCS 2000

Monitoring: break monotoring by Cameras

Pope Reel: Hydraulic operated with reel spool change system and accelerator

Vacuum: by Turbair Blower RC-4A-3(4)-N-80, 1,4MW, 1800A, 500V, 148m3/min

Lubrication system: wet end and dryer part,

greasing system: wet end and press part

Hood with heatrecovery, fully closed

Main drive: ABB drive motors, DC drives, gearboxes, Control System Valmet

Slitter rewinder:

Jagenberg VariStep VS65, 4100mm working width, made 1984

- Paper machine

- paper machine

- paper machine

- paper machine

- paper machine