Chemical Pulp Production Line 200.000 tpy

This product is not available at the moment. Please contact our customer service for more info.

-

Print this page

- Product ID: VAK10462

- Name: Chemical Pulp Production Line 200.000 tpy

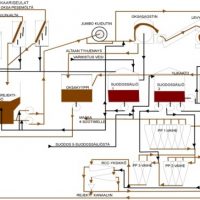

CHEMICAL PULP PRODUCTION LINE

* Capacity 200 000 tpa

Raw material Handling

2 Barkers

2 Chippers, RWC 12-3000, Rauma-Repola (1971,1988)

5 Batch digesters, YIT (1965, 2002-2003)

1 Continuous digester, 30 000tpa, C-E Bauer

(1970, rebuild 1978)

Chemical Recovery

* Lime kiln, (1975, rebuilds 2005/2006)

* Recausticizing system, Dorr-Oliver (1969)

* Evaporator, 7 effects, Rauma-Repola

(1966, rebuilds 1998 and 1999)

* Lime kiln, Smidth (1960, rebuild 1998)

* Evaporator, 10 effects, Rauma-Repola (1971/1975)

* Bleaching unit

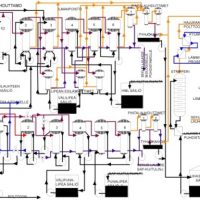

Scope of plant

The scope of the plant covers major sections and main machinery of the process according listing below:

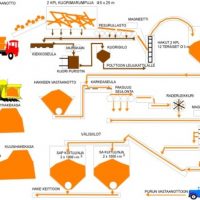

* Wood handling covering debarking, chipping, chip screening

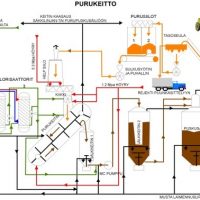

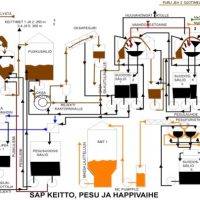

* Cooking

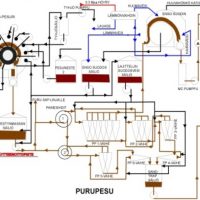

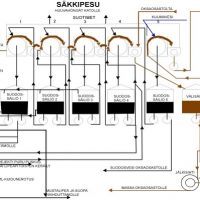

* brown stock washing

* knot and reject handling

* pulp screening

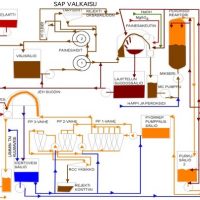

* bleaching by oxygen and peroxide

* spent liquor evaporation

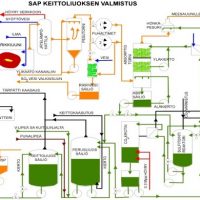

* recausticizing

* lime kiln

* malodorous gases treatment

* turbine generator (from other mill)

Certain major sections of the process are not included and are listed below:

* recovery boiler

* fresh water treatment

* effluent treatment

* electricity main distribution and distribution transformers

(6kV/600V)

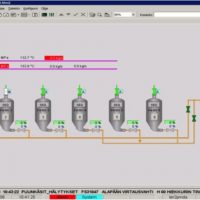

* mill automation: Distributed Control System (DCS)

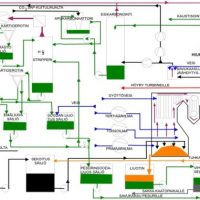

PULP PRODUCTION LINES

| GRADES | INT AT MILL | TOTAL INT | TOTAL PULP |

| bl sd sa | 50 | 50 | 50 |

| bl sw sa | 130 | 130 | 130 |

| Unbl sd sa | 30 | 30 | 30 |

| unbl sw sa | 30 | 30 | 30 |

Pulp mill raw material :92% SW; pine, spruce

By-products :tall oil, 120t/d

turpentine

tall oil products, 25t/d

Purchased Fibres :bl hw sulphate

deinked pulp

bl sw sulphate

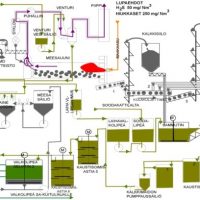

PULP MILL INFORMATION

| Raw material handling: |

2 barkers 2 chippers, RWC 12-3000, Rauma-Repola, 1971 1 chipper, RWC-3000, Rauma-Repola, 1988 |

| Cooking: | 1 continuous digester for unbl sd sa, a 30 (1000t/a)C-E Bauer, 1970 /1978 1 batch digester for bl & unbl sw sa, a 0(), 1965 2 batch digesters for bl & unbl sw sa,a 0(), YIT,2002 2 batch digesters for bl & unbl sw sa,a YIT, 2003 1 batch digester for unbl sw sa,a 0(), YIT, 2004 |

| Chemical recovery: |

1 lime kiln, for sw sa, 1975/2005/2006 1 recausticizing system, for sw sa, Dorr-oliver, 1969 1 recovery boiler, for sw sa, a 1150 tds/d, Tampella, 1975/1987, 1993 1 evaporator, 7 effects, for sw sa, 150t/h, Rauma-Repola1966/1998/99 1 lime kiln, for sw sa, 150t/h, Smidth,1960/1998 1 evaporator, 4 effects, for sw sa, a50t/h, Rauma-Repola 1971 1 evaporator, 6 effects, for sw sa, a75t/h, Rauma-Repola 1975 |

| Bleaching: | O, for sw sa 200 (1000t/a) Andritz 2007 1, XN, for sw sa, 200 (1000t/a), Andritz 2007 |