Pulp mill sold in sections/parts 350,000 t / y In Finland

-

Print this page

- Product ID: VAK11347

- Name: Pulp mill sold in sections/parts 350,000 t / y In Finland

Pulp mill.

Some equipment are already marked for internal use.

Ask us for more information

FIBERLINE MACHINERY

Brownstock washing

Drum displacement washing plant / Ahlström (1995)

200 AD ton/d

DD4060.4 LCV (2 pcs … DD29 and DD30)

Oil hydraulic twin drive (MB-800-N)

Filtrate tank Veff/tot = 440 / 550 m3 (d = 10000, H = 7000) o Foam tank V = 200 m3 (d = 5000, H = 10000)

Discharge tank V = 67 m3 (d = 2500, H = 14900) / Andritz (2018)

Oxygen delignification and white liquor oxidation

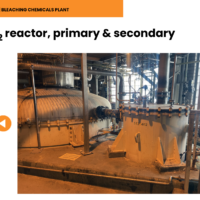

- Two-stage MC oxygen bleaching plant 1200 AD ton/d / Kamyr (1990) and Kvaerner (1996)except where noted otherwise

o Reactor #1 (1996) V = 338 m3 (d = 4000, H = 32500)Pmax =9,0barG /Tmax =180°C

Feed pump MC150-470-1 / Andritz (2018)

Chemical mixer AC30-20FS / Andritz (2018)

Oxygen pre-mixer OXS300 / Andritz (2018)

Flow distributor Type 600

Outlet device MCF600-200GR / Andritz (2018)o Reactor #2 (1990) V = 472 m3 (d = 4500, H = 34750) Pmax =9,0barG /Tmax =200°C

Feed booster MC43-200 / Sulzer (2017)

Steam feeder Solaris AFS300 / Andritz (2018) Chemical mixer AC30-20FS / Andritz (2018) Oxygen pre-mixer OXS300 / Andritz (2018)

Flow distributor Type 600Outlet device Top Scraper 4500

Blowtank V = 27 m3 (d = 1500, H = 15000) Discharge pump MCP 30/20 / Kamyr (1990)o Pressure diffuser TD70B (1990) V = 84 m3 (d = 2620, H = 22685) Pmax =10,0barG /Tmax =120°C

Filtrate screen Sorter M800 / Ahlström (1987) FiltratetankV=210m3 (d=6000,H=7500)White liquor oxidation plant 1,75 ton/h NaOH (~300 m3/d WL) / MoDo Chemetics (1990)

Reactor V = 290 m3 (d = 5800, H = 11000)

BuffertankV=33m3 (d=3500,H=3500)

Positive displacement blower Aerzener II GmB16.12 (Q = 4400 m3/h)

Oxygen plant 940 m3/h (NTP, 93 % O2) 14 barG / Messer-Griesheim (1996)

Pressure vacuum swing adsorption technology (synthetic zeolite molecular sieves)

Adsorber(2pcs)V=60m3 (d=3600,H=7000)

BuffertankV=70m3 (d=3000,H=11000)

Liquid oxygen back-up unit (64 ton LOX, Pmax = 18 barG)

Vaporizer Q = 3000 kg/h O2

Screening

Three-stage cascade arrangement (pressure screens, Pmax = 6,0 barG) with deknotting and re-ject handling 1300 AD ton/d / Andritz (2018) except where noted otherwise

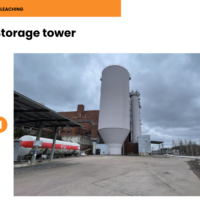

MC storage tower V = 2000 m3 (d = 10500, H = 28200) / Enso-Gutzeit (1975)

Stainless steel cladding in the bottom part SS2343

o Brown-stock screening feed tank V = 140 m3 (d = 6000, H = 5000) / Enso-Gutzeit

(1975)

o Feed pump A63-400 / Sulzer (2018)

o Deknotting screen ModuScreen CT80 (ø10) / Andritz (2016)

o Knot washer KW4 (ø10) / Andritz (2016)

o First stage screen ModuScreen FT60 (slot size 0,18 mm)

o Second stage screen Sorter M 800 (slot size 0,25 mm) / Ahlström (1987)

Quick Shell Dolphin rotor / Andritz (2011)

Third stage screen Sorter M 400 (slot size 0,25 mm) / Ahlström (1987)

Quick Shell Dolphin rotor / Andritz (2011) o Reject handling

Light reject pressure screen CentriFilter M 200 / Ahlström (1987) Screen HydraScreen 2-28 / Ahlström (1990)

Centrifugal cleaner SandTrap 624-T (3 pcs) / Ahlström (1990)

HB300 HD-3 upgrade / Andritz (2011) Reject washer KW4R (ø4) / Ahlström (1994)

o Pressure thickener PT10; V = 9 m3 (d = 1948, H = 3200), Pmax = 6,0 barG

Bleaching

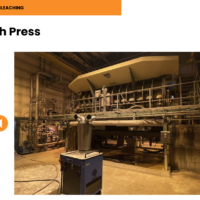

Four-stage arrangement 1150 AD ton/d / Ahlström (1998) except where noted otherwise;

ECF sequence: D0–EO(P)–D1–P(O) / TCF sequence: Q– EO(P)–PAA–Q–P(O) o FeedtankV=210m3 (d=6000,H=7500)/Kamyr(1990)

o Feed line separator 30-40- ø315-15 / Kvaerner (1996)

o Wash Press 1555 (in use) / Kamyr (1990)

Vat and drum replaced in 2000 by Kvaerner

Drum (d = 1500, Leff = 5400) … Oil hydraulic twin drive (MA-800-N)

Press roll d = 1100, Leff = 5400) … Oil hydraulic drive (MA-141-N)

MC drop leg MDL-L V = 5 m3 (d = 800/1000, H = 8000) / Ahlström (1998) Bleach plant feed pump MCA43-150 + AHF75-MC1

Filtrate collection tank V = 180 m3 (d = 6000, H = 6500) / Kamyr (1990)

Filtrate tank V = 2000 m3 (d = 10500, H = 28200) / Enso-Gutzeit (1975)

Stainless steel cladding in the bottom part SS2343

Feed line separator PLS 40/50 / New, Andritz (2023)

Hot water tank V = 114 m3 (d = 3500, H = 16100) / Kamyr (1990)

Evaps secondary condensate

Drum (2 pcs, d = 1500, Leff = 4600), W1.4462

MC drop leg MSP14-6 V = 9 m3 (d = 1419, H = 6230) / New, Andritz (2023) Bleach plant feed pump MCE52-200 + MCDP3-50 / Sulzer (2017)

D0/Q stage

Feed tank V = 40 m3 (d = 3500, H = 16100), W.1.4462

Feed pump MCA43-150 + AHF75-MC1

Chemical mixer AM25-20 (Ti)

Up-flow reactor V = 410 m3 (d = 4600 (4500), H = 33950), refractory-lined

ECF design: 75 °C, tRES,nom. = 60 min

Tower outlet device ATS-MC-4500-TL (Ti)

MC drop leg MDL-XL V = 18 m3 (d = 700/1400, H = 12100), W1.4547 Washer feed pump MCA43-150 + AHF75-MC1

Drum displacement washer DD4040.1,5 MCV, W1.4547

Filtrate tank V = 118 m3 (d = 5000, H = 6600), FRP

EO(P) stage

Feed tank (MC drop leg) MDL-L V = 5 m3 (d = 1000, H = 8000), W1.4436 Feed pump MCA43-150 + AHF75-MC1

MCE HydroFit upgrade incl. FC drive control / Sulzer (2019) Chemical mixer AM30-20FS

MC flow discharger 40P2-14

Up-flow reactor V = 417 m3 (d = 4500, H = 31600), W1.4436

- ECF design: 80 °C, tRES,nom. = 60 min

- Pmax =10,0barG /Tmax =120°C

Reactor outlet device/pump MCF600-200GR (Vertical), W1.4436 Chemical mixer AM30-20FS

MC flow discharger 40P2-14

Up-flow reactor V = 417 m3 (d = 4500, H = 31600), W1.4436

- ECF design: 80 °C, tRES,nom. = 60 min

- Pmax =6,0barG /Tmax =120°C

Reactor outlet device 40P2-14

Blow tank V = 235 m3 (d = 4000, H = 23350), W1.4436

MC drop leg MTB-700 V = 0,5 m3 (d = 700, H = 1250), W1.4436 Washer feed pump MCA43-150 + AHF75-MC1

Drum displacement washer DD4040.1,5 MCV, W1.4436

Filtrate tank V = 118 m3 (d = 5000, H = 6600), FRPo D1/PAA stage

Feed tank (MC drop leg) MDL-L V = 5 m3 (d = 1000, H = 8000), W1.4436 Feed pump MCA43-150 + AHF75-MC1

Chemical mixer AM25-20 (Ti)

MC flow discharger 40P2-14/4 (Ti)

Up-flow reactor V = 1126 m3 (d = 5970 (5850), H = 47500), refractory-lined

ECF design: 75 °C, tRES,nom. = 180 min

Tower outlet device ATS-MC-6000-TL (Ti)

MC drop leg MDL-XL V = 18 m3 (d = 700/1400, H = 12100), W1.4547

Washer / Q reactor feed pump MCA43-150 + AHF75-MC1

Q reactor (up-flow) V = 35 m3 (d = 1800, H = 17700), W1.5457 … By-passed

- ECF design: 75 °C, tRES,nom. = 10 min

- Pmax =6,0barG /Tmax =120°C

Drum displacement washer DD4040.1,5 MCV, W1.4547 Filtrate tank V = 118 m3 (d = 5000, H = 6600), FRP

P(O) stage

Feed tank (MC drop leg) MDL-L V = 5 m3 (d = 1000, H = 8000), W1.4436 Feed pump MCA43-150 + AHF75-MC1

MCE HydroFit upgrade incl. FC drive control / Sulzer (2022) Chemical mixer AM25-20FS

MC flow discharger 40P2-14

Up-flow reactor V = 781 m3 (d = 5600, H = 37500), W1.4436

- ECF design: 80 °C, tRES,nom. = 120 min

- Pmax =6,0barG /Tmax =120°C

Reactor outlet device 40P2-14/2, W1.4436

Drum displacement washer DD4040.1,5 MCV, W1.4436

MC drop leg) MDL-L V = 5 m3 (d = 1000, H = 8000), W1.4436 Bleached pulp pump MCA43-150 + AHF75-MC1

Filtrate tank V = 118 m3 (d = 5000, H = 6600), W1.4436o MC storage tower V = 10000 m3 (d = 17500, H = 50850)

Stainless steel cladding + Upper part (ca. 15%) W1.4436 LC feed pumps to drying department- APP51-250 (DM4)

- APP43-250 (DM6)

o Semi-bleached pulp booster pump MCA43-150 (not in use

Bleaching chemicals plant

Two-line Mathieson plant (8+10 ton/d ClO2, Rauma-Repola / 1979&1985) modified to AHP

technology (Sterling Pulp Chemicals) by Finnish Chemicals in 2002 utilizing H2O2 in an aqueous solution as reducing agent instead of SO2 with 20 ton/d ClO2 capacity

o H2O2 storage tank V = 80 m3 (d = 3800, H = 7500) / 1998, located at the bleach plant DosingtankV=2m3 (d=1800,H=2000)/2002

o Concentrated H2SO4 tanks (2 pcs) V = 50 m3 (d = 4050, H = 4250) / 1993 & 2015 DosingtankV=6m3 (d=2000,H=2200)/1985

o NaClO3 storage tank V = 185 m3 (d = 6300, H = 6900) / 1979

o Primary ClO2 reactor V = 34 m3 (d = 3760, H = 5350) / RR (1985), modified by FC

FRP lining … completely restored latest in 2022

o Secondary ClO2 reactor V = 4 m3 (d = 1300, H = 3550) / RR (1985)

FRP lining … completely restored latest in 2018

o ClO2 absorption column V = 18 m3 (d = 1300, H = 14000) / FC (2002)

o Absorption column offgas scrubber V = 10 m3 (d = 1000, H = 13500) / RR (1979) o Aqueous ClO2 storage tanks (2 pcs) V = 330 m3 (d = 6500, H = 11750)

All FRP / 2004 & 2021

o SpentacidFRPcolumnV=10m3 (d=350,H=2000)/RR(1985) o Spentacidtanks(2pcs)V=80m3 (d=4000,H=6400)

#1 – SS/Ti construction with an FRP lining completely restored latest in 2018

#2 – All FRP / 2019

o DiluteH2SO4 tank#1V=33m3 (d=3400,H=3750)/1995

o DiluteH2SO4 tank#2V=21m3 (d=2860,H=3100)/2017

o Dilution air compressor Atlas Copco ZE 4 VSD (2011)

o Dilution water cooler (3 pcs) 2 x Carrier 30HXC 190 + 1 x Carrier 30HXC 230

Drying and handling of pulp bales

Pulp dryer DM4 (4200 mm); a fourdrinier machine with a pick-up roll and a dryer with

steam-heated cylinders, a cutter-layboy and a bale press … 600 AD ton/d o Stock preparation

Pulp stock chest V = 100 m3 (d = 5000, H = 4800) / Ahlström (1982) Machine chest V = 50 m3 (d = 3800, H = 4500) / Ahlström (1982)

Pressure screening

ModuScreen AL5 (Guard) + Sorter M 1600 / Ahlström (2000 + 1990) Three-stage hydrocyclone screening / Ahlström (1987)

- Enso TwinCleaner 67 ø1000 … max 31 pcs twin cyclones

- Enso TwinCleaner 67(66) ø650 … max 12 pcs twin cyclones

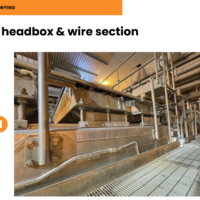

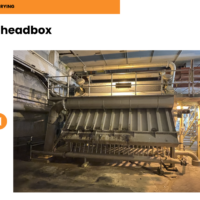

- Enso TwinCleaner 67(66) ø370 … max 3 pcs twin cycloneso Wet end … originally a Kamyr wetlap machine delivered by Ahlström (1964) Headbox (b = 4300) Ahlström / Valmet (2014)

- Refurbished headbox of Norrsundet’s TM-5 delivered in 1991

- Flow rate 17 500 – 25 000 l/min / Max speed 180 m/min

- Design consistency 1,4 %

- Base weight 650 – 950 g/m2 Wire section (L = 10000) with a forming table / Ahlström (1982)

- Modified by IBS in 2019: New steam box incl. a control unit, newsuction box and sets of foils to existing hydrofoil and vacuum boxes

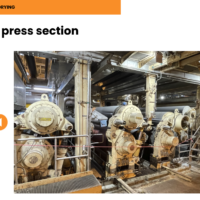

- Wire: b = 4500, L ≈ 25000 Press section (b = 4500) / Ahlström (1982)

- Rubber-lined felt press rolls and an oil hydraulic loading of press nipswith press #4 added by Valmet in 1990

- (Press #1) Pick-up roll (ø906, b = 4650) Ahlström / Ahlström (1982)o Modified by Valmet in 2014: Runtime adjustment of the width of the suction zone and new spray water piping and nozzles for the internal sealing strips

- Press #2 Roll (ø915, b = 4550) / Ahlström (1982)

- Press #3 Rolls (2 pcs á ø915, b = 4550) / Ahlström (1982)

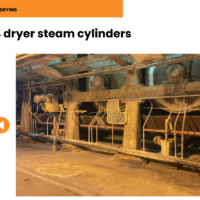

- Press #4 Rolls (2 pcs á ø915, b = 4550) / Valmet (1990)o Dryer … Steam cylinder dryer with 73 pcs dryer cylinders (ø1500, b = 4450) 62 pcs / Ahlström (1964) 11 pcs / Ahlström (1982) Pmax = 6,1 barG / 4,9 barG (Tmax = 120 °C)

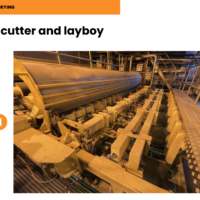

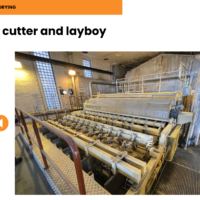

o Cutter and layboy (5 x 840 x 750) / Ahlström (1982) Layboy and cross-direction cutter rebuilt in 1989 by Valmet for 650 AD ton/d; improved heating of the cutter roll and the bed knife beamo Bale press 1000 ton / Ahlström (1981)

o Stacker 1200 AD ton/d / Pukero (2007)

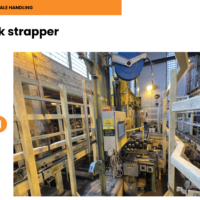

o Stack strapper (4 x 250 kg) Cranston 60B023 / Valmet (1993)

o Drive control with Vacon’s frequency converters / Honeywell (2006) o Online quality control Moisture and base weight: Experion MX Q4000 / Honeywell (2012)

Web inspection system: PQV 5020 dirt count analyzer / Valmet (2015) Brightness: Experion MX Color Q4215-60 / Honeywell (2015)

Pulp dryer DM6 (4200 mm); a Kamyr wetlap machine with rifled feltless press rolls and an airborne Fläkt dryer, a cutter-layboy and a bale press … 600 AD ton/d

o Stock preparation

Pulp stock chest V = 100 m3 (d = 5000, H = 4850) / Ahlström (1983) Machine chest V = 50 m3 (d = 3800, H = 4500) / Ahlström (1982)

Pressure screening

ModuScreen AL5 (Guard) + Sorter M 1600 / Ahlström (1998 + 1990) Three-stage hydrocyclone screening / Ahlström (1990)

- Enso TwinCleaner 67 ø1275 … max 55 pcs twin cyclones

- Enso TwinCleaner 67(66) ø650 … max 12 pcs twin cyclones

- Enso TwinCleaner 67(66) ø370 … max 3 pcs twin cycloneso Wet end … a Kamyr wetlap machine

Headbox + Suction mould / Ahlström (1982)

Cylinder (ø3500, b = 4200) rebuilt (enhanced) in 2018 by Valmet Press #1 / Ahlström (1982)

Rifled press rolls (ø800, b = 4200) … replaced in 2014 by Valmet uti- lizing refurbished old rolls delivered originally to Kemi Oy

Press #2 / Ahlström (1964)

Rifled press rolls (ø800, b = 4200) / Valmet (2015)

Press #3 / Ahlström (1982)

Rifled press rolls (ø900, b = 4200) / Valmet (2004)

o Dryer

FCG airborne dryer 600 AD ton/d (bmax = 4330) / ABB (2000)

18 decks w/ 21 towers (incl. the end towers) … 102 pcs FD circula- tion fans (nom. power consumption ca. 1,4 MW)

L = 41000, b = 8800, H = 7250

- Base weight 1100 – 1600 g/m2 … design 1490 g/m2, speed 60 m/min

- Pmax = 12,7 barG (Tmax = 205 °C) … design 2,3 barGo Cutter and layboy (5 x 840 x 750) / Ahlström (1982)

Rebuilt from an earlier DM2 cutter (1964, Ahlström) with a new layboy

Cutter rebuilt in 2002 by Metso; improved heating of the cutter roll and thebed knife beam

o Bale press 1000 ton / Ahlström (1982) Hydraulic system rebuilt in 1990 by Valmet

o Stacker 1200 AD ton/d / Pukero (2007)

o Stack strapper (4 x 250 kg) Cranston 60B023 / Ahlström (1982) o Drive control with ABB’s frequency converters / ABB (2000) o Online quality control Moisture and base weight: Accuray / ABB (2000)

Updated in 2018 by ABB

Web inspection system: PQV 5020 dirt count analyzer / Valmet (2016) Includes web break monitoring

Brightness: Experion MX Color Q4215-60 / Honeywell (2016)

Bale handling

- Chain conveyor system 600 + 600 AD ton/d incl. pulp storage area / Ahlström (1982)o The tipping device for strapped bale stacks (1000 kg) replaced in 2002 by Pukero

- Export pulp bale handling 1200 AD ton/d / Pukero (2007)o Wrapper applier … replaced with Valmet Wrapper Applyer (Roll ERC) in 2022 o 2 pcs 250 kg bale strappers Cranston 986

o Wrapper folder

o Stackero Bundle strapper Cranston 60B040Fiberline analyzers and distributed control systems

- Debarking quality controlo Woodsmart (incl. the equipment for BarkSmart, ProfiSmart, FillSmart and LogSmart modules) / TeknoSavo (2021)

- Brown-stock and bleached pulp kappa number and brightness control o Valmet Kappa QC / Valmet (2017)

- Pulp (fiber property) analyzer

o KajaaniMAP / Metso (2006) - Bleach plant vent gas scrubber control

o KemTrak ClO2 analyzer / Kontram (2021) - ClO2 generator control … not installed

o Photometric analyses of ClO2, Cl2, NaClO3 and H2SO4 / WIC Systems (2023) - Wastewater treatment plant effluent control

o Photometric analysis of COD / WIC Systems (2006) o Photometric analysis of Paq / WIC Systems (2011) - DCS architecture … 3 pcs “systems” set up by Honeywell o #1 “Bleaching” … Total Plant Alcont R690 33 pcs process controllers (i.e. VPRs and XPRs) from 1999 onward o #2 “Drying” … Total Plant Alcont R682.SP1 20 pcs process controllers (i.e. VPRs and XPRs) from 2000 onward o #3 “Screening” … Total Plant Alcont R690 4 pcs process controllers (i.e. VPRs and XPRs) from 2007 onward

Selected machinery from the Chemical Recovery Area and the Power Plant

Machinery and units installed in recent years *)

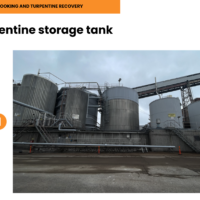

- Tall oil plant 3,5 ton/h CTO / Pöyry (2014)o HDS separator V = 40 m3 (d = 2500/4590, H = 9000) W1.4539 / W.14432 (CTO wetted parts)

- Falling film evaporator (HA5/2) / Rinheat (2020) o A = 3400 m2 (d = 2800/3300, H = 21700) Tube size ø50,8 (s=1,2) / L = 13000 o Pmax/min = 4,0/-1,0 barG (Tmax = 152 °C)

o W1.4301 / W1.4307 - Condensate stripping falling film evaporator (HA5/6) / Rinheat (2017) o A = 3000 m2 (d = 3500/4600, H = 17000) Tube size ø60 (s=1,0) / L = 9000 o Pmax/min = 0,5/-1,0 barG (Tmax = 110 °C) o W1.4301 / W1.4307

- Evaps auxiliary condenser for super concentrator vapors / Rinheat (2019)

o A = 230 m2 (d = 1300, H = 10000)

o Pmax/min = 4,0/-1,0 barG (Shell) / 6,0/-1,0 barG (Tubes) / Tmax = 120 °C

- Electrostatic precipitators for the lime kilns (2 pcs) / ECP (2020)

o b = 5100, L = 15700, H = 26500 (Qin,max = 9,0 m3NTP/s, wet) Tmax = 350 °C (Tmax-max = 400 °C) Pmax / Pmin = +6500 / -6500 Pa

o Guaranteed particulate emission max 20 mg/m3NTP (6% O2, dry) Max 68 g/m3NTP (6% O2, dry) in

o Three-field system A-B-C (L = 4500 each) b=4400,H=6000/Acoll =1780m2o Three-phase transformer-rectifier power supply G_QE (Kraft Powercon) GBQE 100/500- μ (A field)

GBQE 90/600-μ (B and C fields)

MicroKraft MK4 controllerso Laser optical particulate measurement system / PCME (2020) ProScatter sensor QAL 181 - ID flue gas fans for the lime kilns (2 pcs)

o ESMB-090-7-LG000D-1475-A-1-ER-KT / Koja (2020) - DCS architecture … “system” set up by Honeywello “Recaust” … Experion PMD R800.4 HotFix1r2

9 pcs process controllers (i.e. various types of FCs) from 2014 onward Contains parts related to lignin extraction and lignin processing - Also available recfovery boiler # 10 Tampella 1965 and # 11 Tampella 1986 110 KW

*) Excluding any equipment related to the infrastructure such as steam boilers and the steam central (incl. turbogenerators, auxiliary condensors etc.), water treatment (incl. waste water treatment plant), compressed air and power distribution systems etc.