Groundwood plant. GW1 370 Bdt/d. GW2 360 Bdt/d

-

Print this page

- Product ID: VAK11280

- Name: Groundwood plant. GW1 370 Bdt/d. GW2 360 Bdt/d

- Attachments:

Basic Information

• Two separate process lines GW1 and GW2

• GW1 consists of 3 lines with 6 Tampella T-1815 grinders. Production 370 Bdt/d – CSF 55 ml

– Motors specified separately

• GW2 consists of 4 lines with 8 Tampella T-1815 grinders. Production 360 Bdt/d – CSF 40 ml

– Motors specified separately

• In total 4 reject refiners Sunds Defibrators SD52, 3,5 MW motors

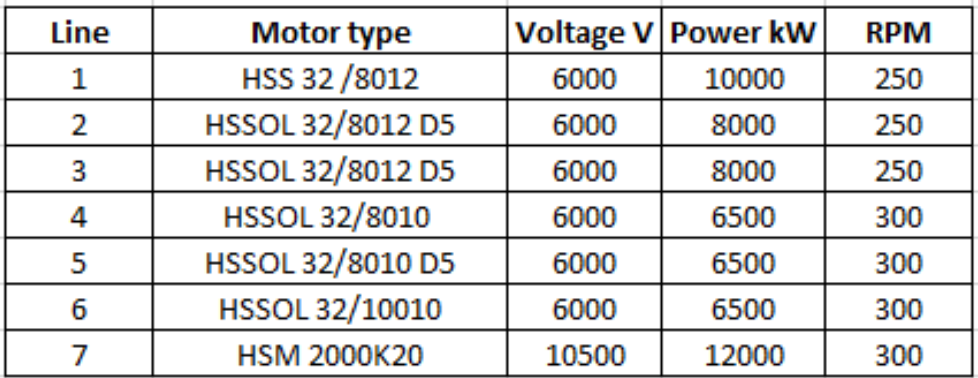

Grinder motors

• Varying voltages, rpms and motor powers • GW1 lines 1,2 and 7

• GW2 lines 3,4,5 and 6

GW1 apparatus

• 6 Tampella T-1815 grinders

– Stones Norton A701 N 7 V21 7TR5 (varying condition)

- 6 vibrating screens Valmet TS1000L

- Shive crusher Tampella TM-500

- Main screen Valmet MUST FS-703E

- Disc filter GL&V VDF 5,2-15(17)/325

- 2 reject thickeners Kvaerner SP45SL

- Transport screws and plug feeders

- 2 reject refiners Sunds Defibrators SD52

- Cyclones and plug dischargers

- 2 reject screens Tampella TL200T

GW2 apparatus

- 8 Tampella T-1815 grinders

- – Stones Norton A701 N 7 V21 7TR5 (varying condition)

- – Line nr 6 log transporters are different and a separate safety training should be done if sold (line originally from Hylte)

- 8 vibrating screens Valmet TS1000L

- Shive crusher Tampella TM-500

- Main screen Valmet TAP703E

- Disc filter GL&V VDF 5,2-18(20)/325

- 1 reject thickeners Kvaerner SP45SL

- Transport screws and plug feeders

- 2 reject refiners Sunds Defibrators SD52

- Cyclones and plug dischargers

- 1 reject screen Tampella TAP200