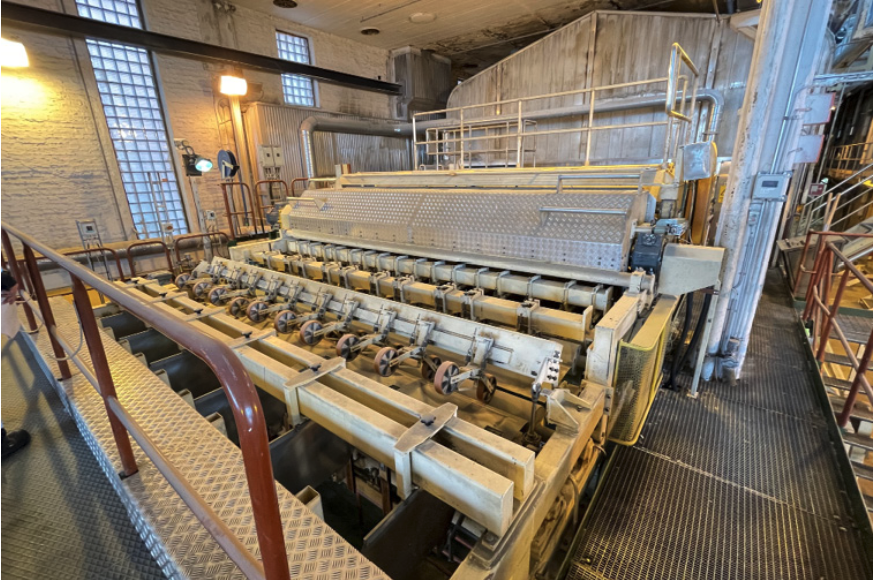

PULP DRYE 4200 mm 600 AD ton / day, a fourdrinier machine. AHLSTRÖM

-

Print this page

- Product ID: VAK11349

- Name: PULP DRYE 4200 mm 600 AD ton / day, a fourdrinier machine. AHLSTRÖM

Drying and handling of pulp bales, pulp dryer DM4 4200 mm

A fourdriniermachine with a pick-up roll and dryer with steam-heated cylinders, a cutter-layboy and bale press … 600 AD ton/d

Stock preparation

Pulp stock chest V = 100 m3 (d = 5000, H = 4800) / Ahlström (1982)

Machine chest V = 50 m3 (d = 3800, H = 4500) / Ahlström (1982)

Pressure screening

ModuScreen AL5 (Guard) + Sorter M 1600 / Ahlström (200 + 1990)

Three-stage hydrocyclone screening / Ahlström (1987)

Enso TwinCleaner 67 d=1000 … max 31 pcs twin cyclones

Enso TwinCleaner 67 (66) d=1000 … max 12 pcs twin cyclones

Enso TwinCleaner 67 (66) d=370 … max 3 pcs twin cyclones

Wet end … orginalyy a Kamyr wetlap machine delivered by Ahlström (1964)

Headbox (b = 4300) Ahlström / Valmet (2014)

Refurbished headbox of Norrsundet’s TM-5 delivered in 1991

Flow rate 17 500 – 25 000 l/min / Max speed 180 m/min

Design consistency 1,4 %

Base weight 650 – 950 g/m2

Wire section (L = 10000) with a forming table / Ahlström (1982)

Modified by IBS in 2019: New steam box incl. a control unit, new suction box and sets of foils to exsisting hydrofoil and vacum boxes

Wire: b = 4500, L = 25000

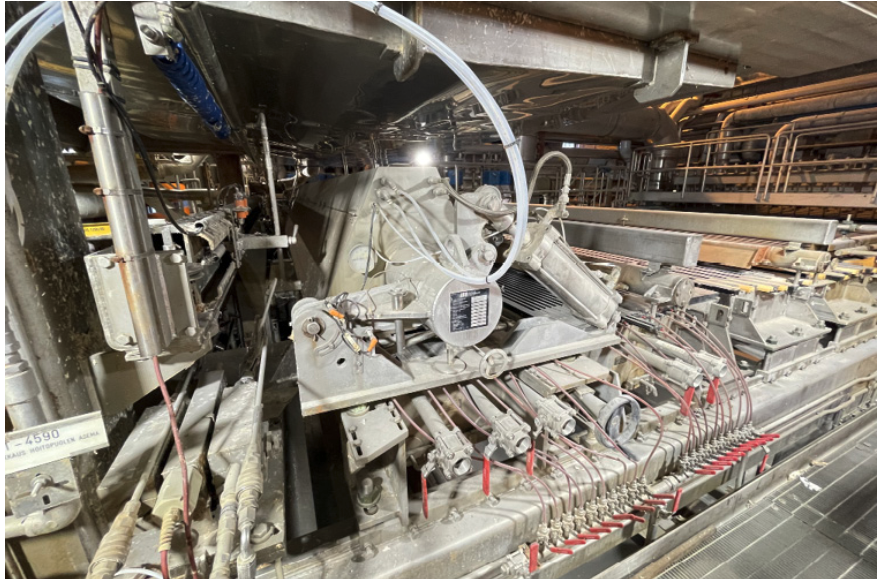

Press section (b = 4500) / Ahlström (1982)

Rubber-lined felt press rolls and an oil hydraulic loading of press nipswith press #4 added by Valmet in 1990

(Press #1) Pick-up roll ( d = 906, b = 4650) Ahlström / Ahlström (1982)

Modified by Valmet in 2014 : Runtime adjustment of the width of the suction zone and new spray water piping and nozzles for the internal sealingstrips

Press #2 Roll (d= 915, b = 4550) / Ahlström (1982)

Press rolls #3 (2 pcs a´d = 915, b = 4550) / Ahlström ( 1982)

Press rolls #4 (2 pcs a´d = 915, b = 4550) / Ahlström ( 1982)

Dryer … Steam cylinder dryer with 73 pcs dryer cylinders (d = 1500, b = 4450)

62 pcs / Ahlström (1964)

11 pcs / Ahlstöm (1982)

P max = 6,1 bar G / 4,9 bar G (Tmax = 120 degrees )

Cutter and layboy (5 x 840 x 750) / Ahlström (1982)

Layboy and cross-direction cutter rebuilt in 1989 by Valmet for 650 AD ton/d; improved heating of the cutter roll and the bed knife beam

Bale press 1000 ton / Ahlström (1981)

Stracker 1200 AD ton/d Pukero (2007)

Stack strapper (4 x 250 kg) Cranston 60B023 / Valmet (1993)

Drive control with Vacon’s frequency / Honeywell (2006)

Online quality control

Moisture and base weight: Experion MX Q4000 / Honeywell (2012)

Web inspection system : PQV 5020 dirt count analyzer / Valmet (2015)

Brightness : Experion MX Color Q4215-60 / Honeywell (2015)

Note, Some devices may be reserved for internal use, please ask.