PULP DRYING LINE 4200 mm Ahlström with Kamyr wet lap machine 600 AD ton / d

-

Print this page

- Product ID: VAK11348

- Name: Pulp drying line DM6

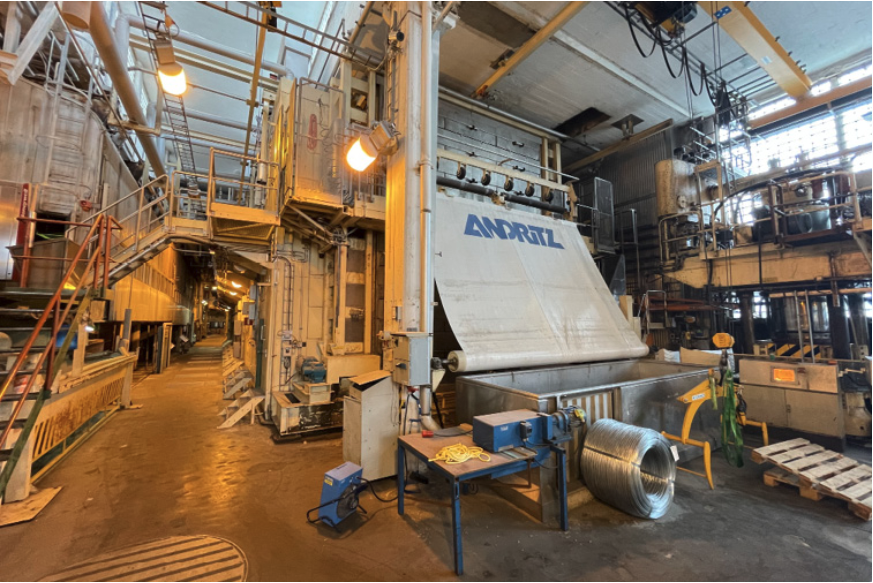

PULP DRYING LINE DM6

Pulp dryer DM6 4200 mm, a Kamyr wetlap machine with rifled feltness press rolls and an airborne FLÄKT dryer, a cutter-layboy and a bale press 600 AD ton/d

Stock preparation

– Pulp stock chest V = 100 m3 ( d = 5000, H =4850 ) / Ahlström (1983)

– Machine chest V = 50 m3 (d = 3800, H = 4500) / Ahlström (1982)

– Pressure screening ModuScreen AL5 (Guard) + Sorter M 1600 / Ahlström (1998+1990)

Three-stage hydrocyclone screening / Ahlström (1990)

Enso TwinCleaner 67 d=1275…. max 55 pcs twin cyclones

Enso TwinCleaner 67 (66) d=650…. max 12 pcs twin cyclones

Enso TwinCleaner 67 (66) d=370…. max 13 pcs twin cyclones

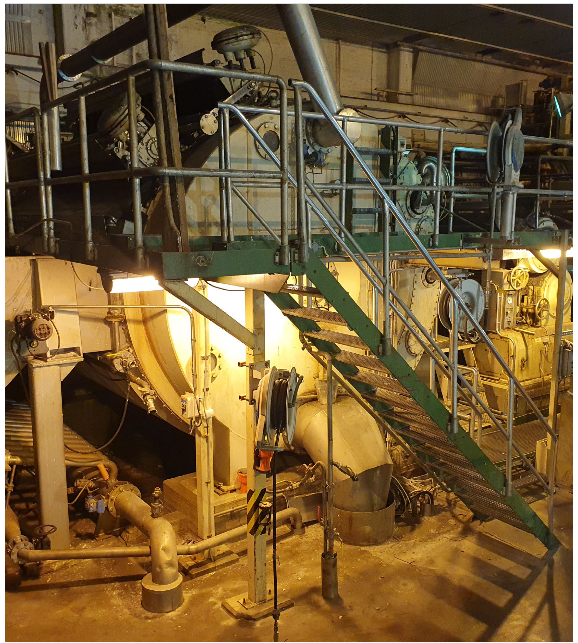

Wet end …. a Kamyr wetlap machine

Headbox + Suction mould / Ahlström (1982)

Cylinder (d=3500, b =4200) rebuilt (enhanced) in 2018 bt Valmet

Press #1 / Ahlström (1982)

Rifled press rolls (d=800, b=4200)…. replaced in2014 by Valmet utilizing refurbished old rolls delivered originally to an other mill.

Press#2 / Ahlström (1964)

Rifled press rolls (d=800, b=4200) Valmet (2015)

Press #3 / Ahlström (1982)

Rifled press rolls (d=900, b=4200) Valmet (2004)

Dryer

FCG airborne dryer 600 AD ton/d (b max = 4300) / ABB (2000)

18 decks w/ 21 towers (incl. the end towers)… 102 pcs FD circulation fans (norm. power consumption ca. 1,4 MW)

L = 41000, b = 8800, H = 7250

Base weight 1100-1600 g/m2… design 1490 g/m2, speed 60 m/min

P max = 12,7 bar G (Tmax=205 degrees)…desing 2,3 bar G

Cutter and layboy (5x840x750) / Ahlström (1982)

Rebuilt in 2002 from an earlier DM2 cutter (1964, Ahlström) with a new layboy

Cutter rebuilt in 2002 by Metso ; improved heating of the cutter roll and the bed knife beam

Bale press 1000 ton / Ahlström (1982)

Hydraulic system rebuilt in 1990 by Valmet

Stracker 1200 AD ton/d / Pukero (2007)

Stack strapper (4×250 kg) Cranston 60B23 / Ahlström (1982)

Drive controll with ABB’s frequency converters / ABB (2000)

Online quality control

Moisture and base weight: Accuary / ABB (2000)

Updated in 2018 by ABB

Web inspection system: PQV 5020 dirt count analyzer / Valmet (2016)

includes web break monitoring

Brightness: Experion MX Color Q4215-60 / Honeywell (2016)

Bale handling

Chain conveyer system 600 ? 600 AD ton/d incl. pulp storage area / Ahlström (1982)

The tipping device for strapped bale stacks (1000 kg) replaced in 2002 by Pukero

Export pulp bale handling 1200 AD ton/d / Pukero (2007)

Wrapper applier … replaced with Valmet Wrapper Applayer (Roll ERC) in 2022

2 pcs 250 kg bale starppers Cranston 986

Wrapper folder

Stracker

Bundle strapper Cranston 60B040

Note, Some devices may be reserved for internal use, please ask.