Voith Tissue Machine 2600mm, 25-40 gms, 12.000 tpa

-

Print this page

- Product ID: VAK10817

- Name: Voith Tissue Machine 2600mm, 25-40 gms, 12.000 tpa

|

Section |

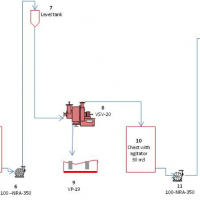

Position in flow sheet |

Description |

INCLUDED |

CUSTOMER SUPPLY |

OPTION OF MOTOR |

|

Pulping |

1 | Conveyor |

X |

||

| 2 | Pulper VV 25 |

X |

75 kW |

||

| 3 | Stock Pump 100-NRA-350 |

X |

15 kW |

||

|

HD Cleaner |

4 | High density cleaner VS-20-M |

X |

|

|

| 5 | Chest with agitator 30m3 |

|

X |

15 kW |

|

| 6 | Stock Pump 100-NRA-350 |

X |

15 kW |

||

| 7 | Level tank |

|

X |

|

|

|

Coarse Screening |

8 | Turboseparator VSV - 20 |

X |

|

55 kW |

| 9 | Vibrating green VP-19 |

X |

3 kW |

||

| 10 | Chest with agitator 50m3 |

|

X |

18,5 kW |

|

| 11 | Stock Pump 100-NRA-350 |

X |

15 kW |

||

| 12 | Level tank |

|

X |

|

|

|

Refining |

13 | Existing refiner |

|

145 kW |

|

| 14 | Chest with agitator 30m3 |

|

X |

15 kW |

|

| 15 | Stock Pump 100-NRA-350 |

X |

15 kW |

||

|

Total |

|

386,5 kW |

Advantages

• easy replacement of most exposed functional elements • low pressure loss connected with low energy demand • efficient operation also with coarsely pulped stocks with high content of impurities • high reliability in service and resistance against fouling • simple operation and maintenance 5. CHEST WITH AGITATOR 30M3 6. STOCK PUMP 100-NRA-350 Flow:950 l/min Consistency:3,6 % 7. LEVEL TANK COARSE SCREENING: 8. TURBOSEPARATOR VSV – 20 Type:VSV 20 Consistency:3,6% Flow:950 l/min Accept:800l /min Screen hole diameter:2,2 mm Possible to include new ADAM control system The washing separators of VSV series belong to a family of pressure screens and separators with increased pulping effects. Based on technology these washing separators are designed for final screening of rejects from primary pressure screens and separators (STU, VDT) in waste paper processing lines. For low capacity lines (up to 50 – 60 tpd) they can provide screening quite separately in one screening stage only. The VSV separators run in programmable periodical cycles according to actual operating conditions. Their function is based on utilisation of hydrodynamic and mechanic effects of properly vaned rotors inbuilt both on inlet and outlet sides of a sorting screen. These rotors provide sufficient flow rates even while separating thick stocks with heavy dirt originating from raw paper, rag and wood pulp. This machine is allowed to be used only for purposes as stated here.Technical and Technological Advantages

• all parts coming in contact with the stock are made of stainless steel, • design simplicity and high efficiency in service, • slotted and bored screens with bores Ø 1,8; 2,2; 2,5 mm providing higher deflaking effects, improved stock turbulence and flow rates. •high reliability in service and resistance against fouling of sorting screens, • possibility to run at high consistency of the stock to be processed up to 4,5 %, • low energy consumption and high efficiency even with coarsely pulped stocks, • easy adaptation to actual technological conditions, • very pure rejects, in fact without loss of fibres. 9. VIBRATING SCREEN VP-19 Type:VP-19 Capacity:10 – 40 tpd Input consistency:0,6 – 2,0 % Wire area:1,38 m2 For processing rejects from VSV Turboseparator. 10. CHEST WITH AGITATOR 11. STOCK PUMP 100-NRA-350 Flow:800 l/min Consistency:3,0 % 12. LEVEL TANK REFINING 13. REFINER Refiner ST500 (supplied with paper machine) can be used 14. CHEST WITH AGITATOR 15. STOCK PUMP 100-NRA-350: Flow:800 l/min Consistency:3,0 %- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA